[Composite Repair Case Study] Repair of Pipe Corrosion and Thinning Due to Rainwater

Composite materials of carbon fiber and epoxy resin for leak sealing and corrosion prevention in reduced thickness piping. *Examples of application in petroleum refining plants are introduced.

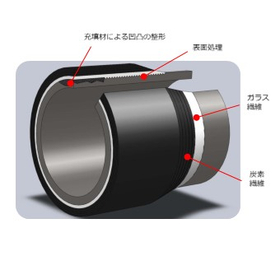

We would like to introduce a case study from a petroleum refining plant. Rainwater entered the 2B dummy pipe support welded to the 3B elbow inside the petroleum refining plant, leading to corrosion over time and noticeable wall thinning. Therefore, we designed it under the condition of "being usable for 10 years without replacing the target piping" and decided to laminate a composite four-layer structure. The composite layers prevent the progression of permanent corrosion and also consider the future leak-stopping effect in case the thinned areas penetrate within the design lifespan (10 years). 【Strengths of Composite Repair】 ■ Design can be tailored to purposes such as strength restoration, leak stopping, and corrosion prevention (strength calculations) ■ Preventive maintenance measures for thinned piping with predictable service life ■ Strength restoration and leak stopping with a maximum design life of 20 years are possible ■ Design and construction in accordance with ISO 24817 ■ Quality that has passed performance tests by third-party organizations *For more details on this method, "Composite Repair Service," please refer to the PDF materials or feel free to contact us. *We also encourage you to check out the case study materials.

basic information

【Effects】 ■Leak prevention (design life of 10 years) ■Corrosion resistance *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(9)

Download All Catalogs

Recommended products

Distributors

Fujifarmanite was established in 1978 as a specialized company for leak repair through a joint venture between Fuji Electric Construction Co., Ltd. (now Fuji Electric E&C Co., Ltd.) and the British company Farmanite. The "Leak Seal" provided by Farmanite addresses leaks of various fluids (steam, air, oil, gas, etc.) in heat sources, power sources, and product manufacturing processes, and is widely used across various industrial sectors. From the perspective of plant maintenance, we have also launched new services such as "Composite Repair," aimed at restoring the strength of thinned pipes, and "Farmaise," which opens stuck valves due to vibration. Our excellent technicians provide high-quality services using the unique technology of the British company Farmanite.