news list

latest news

Regarding the internet and telephone line issues at the Yatsushiro Factory.

Due to a road collapse accident that occurred around 10 AM on January 28 (Tuesday) in the neighboring area, our Yashio factory (including the sales department) is experiencing disruptions to both inte…

31~60 item / All 502 items

-

[Case Study] Stainless Steel Tanks for Craft Beer Production (Mashing and Boiling)

We have added product case studies to the official Nitto Metal Industry website. This is a custom-made stainless steel tank adopted by customers in the food and beverage industry. It is used for producing beer using a handmade method as a new business venture. For more details, please see the related link.

-

You can download the PDF document that experiments with the "method of addition" to suppress foaming.

Foaming can cause various troubles depending on what is being handled. For example, if the foam does not disappear, you cannot proceed to the next process. In such cases, you have to incorporate processes like defoaming or waiting for the foam to dissipate naturally. This hinders work and is inefficient. In other words, even a slight reduction in the amount of foam can lead to improved work efficiency. This document summarizes the experiments conducted on "methods to suppress foaming." Please feel free to download it from the related catalogs at the bottom of the page.

-

[Explanation Material] You can download a PDF document regarding the heat resistance temperature and heating of stainless steel containers.

We sometimes receive inquiries from customers asking, "What is the heat resistance temperature of stainless steel containers?" In this document, we will introduce the heat resistance temperature of stainless steel containers, precautions when heating (warming) contents using stainless steel containers, and frequently asked questions regarding heating. Please feel free to download from the related catalogs at the bottom of the page.

-

The website has been completely revamped.

On February 21, 2023, we reopened our website as an online store. In addition to the ability to purchase customized products, you can now quickly check product prices online. Please take a look! https://www.nitto-kinzoku.jp/

-

A valve specifically designed for bulk materials that can automatically open and close using pneumatic pressure.

The shutter valve series, which has been adopted for filling processes of powders and granules, as well as for the input of raw materials, now includes an automatic opening and closing type. By supplying air to the air cylinder, it can automatically open and close using pneumatic pressure. It can also be linked with other equipment, making it useful for automating processes. You can download materials from the related catalog.

-

Do you know what purposes industrial pressure vessels are used for? [Download explanatory materials available]

A pressure vessel refers to a container designed to hold pressure within it. Nitto Metal Industry Co., Ltd., a manufacturer of stainless steel containers, produces small capacity pressure vessels, primarily ranging from 1L to 200L, used in factories and laboratories, in addition to stainless steel containers for atmospheric pressure. Since these are so-called "industrial pressure vessels," they are rarely seen in everyday life, and it can be difficult to understand their purpose just by looking at the products. This PDF document will explain the specific purposes for which pressure vessels are used, based on examples of products that have been manufactured so far. Please feel free to download and view from the related catalog at the bottom of the page.

-

What is the cleaning method to make stainless steel containers last longer? [Download explanation materials available]

After using a stainless steel container, it is essential to clean the container. However, incorrect cleaning methods can cause scratches or rust. This PDF document introduces important cleaning methods to help prolong the life of stainless steel containers. Feel free to download and view it from the related catalog at the bottom of the page.

-

What are the tips for successfully purchasing a mixer? [Download the explanatory materials]

There are various models of mixers released by different manufacturers, and it is often thought, "There are too many types, I don't know which one is good!" "Will it mix properly?" "How do I buy it?" In this PDF document, we will introduce tips for choosing a mixer that you should know when purchasing one, as well as how to buy a mixer. This is recommended for those who are in charge of purchasing a mixer for the first time and for those who are considering getting a mixer. Feel free to download from the related catalogs at the bottom of the page.

-

Why does powder get clogged? [You can download the explanatory materials]

"Powder clogging" is a common issue when discharging powder from a container. It can lead to variations in product quality due to prolonged discharge times or complete stoppages. But why does the powder discharge poorly (clog)? This document summarizes the causes of powder clogging and the specifications of containers and peripheral equipment to resolve the issue. Please feel free to download from the related catalogs at the bottom of the page.

-

Are you concerned about the mounting position of the free-moving and fixed casters? [You can download the explanatory materials.]

Stainless steel containers are heavier compared to resin containers. If they contain contents or are made with pressure-resistant specifications, they become even heavier. In such stainless steel containers, it is common to use carts or attach caster legs for movement. However, isn't it a small source of stress in your work when they don't move as you expect? In fact, there are several types of casters based on their movement, and by selecting them according to your usage, you can significantly improve work efficiency. This document explains the combination and arrangement of "swivel casters" and "fixed casters" among the various types of casters, tailored to your usage. Feel free to download from the related catalog at the bottom of the page.

-

[Explanation Material] You can download the PDF document on sterilization of stainless steel products.

Stainless steel can be sterilized, but there are stainless steel products that can and cannot be sterilized. There are various types of sterilization, but in this document, we will introduce the sterilization of stainless steel containers (SUS304/SUS316L) manufactured by Nitto Kinzoku Kogyo using an autoclave (high-pressure steam sterilization / 121°C for 20 minutes). Feel free to download from the related catalogs at the bottom of the page.

-

[Explanation Material] You can download the PDF document regarding the compatibility of disinfectants and stainless steel containers.

Recently, there hasn't been a day when I haven't seen alcohol or sodium hypochlorite solution set up. I purchase large quantities, such as in cans or bag-in-boxes, and then divide them into smaller portions. Additionally, depending on the type of disinfectant, there may be cases where dilution is necessary. In such situations, I recommend "stainless steel products suitable for portioning." In this document, in addition to discussing "how compatible are disinfectants and stainless steel?", I will introduce two stainless steel products that are ideal for portioning disinfectants. Feel free to download from the related catalog at the bottom of the page.

-

[Case Study] Customized specifications to reduce filtration time | Cosmetic ingredient filtration container

We have added product case studies to the official Nitto Metal Industry website. This is a custom case of a cosmetic ingredient filtration container adopted by a customer in the cosmetics industry. Based on our lineup of filtration containers, we customized it to reduce the time required for filtration. For more details, please see the related link.

-

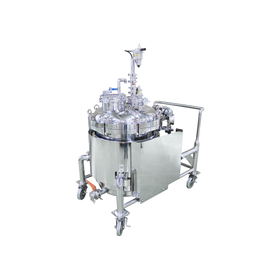

[Case Study] 200L Single Taper Stirring Pressure Unit

We have added case studies of our products to the official Nitto Metal Industry website. This is a custom case of a stirring pressure unit that can be heated and stirred under pressure, adopted by a customer in the cosmetics industry. We have realized various customization requests, including safety measures. For more details, please check the related link.

-

[Technical Column] Products and Customization Examples for Back Pain Relief

The homepage "Technical Column" has been published. Lower back pain accounts for 60% of what is commonly referred to as "occupational diseases." Preventive measures against lower back pain are essential for achieving a safe working environment. Many of the stainless steel tanks and peripheral equipment we handle are sized and weighted to be just manageable by human power. There is a risk of placing a significant burden on the body through repeated tasks that may feel like "it's tough on the back, but I can manage if I push a little." That said, it may be difficult to imagine what kind of design can alleviate this burden. Therefore, in this column, we will introduce products that reduce the strain on the back during daily operations, as well as examples of custom solutions that our customers have actually adopted. For more details, please refer to the "Related Links" section below.

-

The materials recommended for those who wondered, "What is a Bernoulli mixer?" have been renewed!

The "Bernoulli Flow Stirrer" from Nitto Metal Industry can suppress foaming and provide powerful stirring. Some of you may be wondering, "What makes it different from other stirrers?" The explanatory document "What is the Bernoulli Flow Stirrer?" provides a detailed introduction to the mechanism and features of the Bernoulli Flow Stirrer. *In 2023, the cover and content have been completely renewed. It is recommended for those who have previously viewed the document as well as for those who are learning about the Bernoulli Flow Stirrer for the first time. The PDF document can be downloaded immediately within Ipros. For more details, please refer to the related catalog below.

-

Recently popular "craft beer" stainless steel tank set recommended for small-scale brewing [custom orders available].

A stainless steel container manufacturer has designed stainless steel tanks to match the three processes of "mashing, boiling, and fermentation" in beer brewing. With a compact design that does not take up much installation space, it is suitable for small breweries such as those attached to stores. We offer two types based on the shape of the fermentation tank. We can also arrange other surrounding equipment, so please feel free to contact us (chillers, heat exchangers, pumps, hoses, etc.). New product: 【Craft Beer Tank Conical Set】 The fermentation tank is conical in shape, making it easy to remove yeast. It can be manufactured in the desired capacity of approximately 1000L. Customization (optional processing) is possible according to usage. 【Craft Beer Tank Upright Set】 Using this product, it is possible to produce about 100 to 150L of beer. The stainless steel tank can be customized according to the beer capacity produced by the customer and the work processes.

-

A sight glass that is not troubled by window fogging | Flanged wiper-equipped viewing window

We will solve the problem of 'the sight glass is there, but it's not visible due to steam!' When the sight glass fogs up due to steam or when substances adhere to it, visibility can be quickly obstructed. However, with this 'wiper-equipped viewing window,' you can easily restore visibility by simply rotating the internal blade, allowing you to check the interior at any time. This product is designed to be installed on flange fittings, so it can be set up on flanged fittings found on tank lids and similar applications. (There is also a type that can be installed on hygienic fittings.) Custom-made options are available to match the specifications of the flange at the installation site. For more details, please refer to the catalog or related links.

-

[Case Study in the Chemical Industry] Stirring Temperature Control Unit Used for Powder Cleaning with Solvents

This is an example of a stirring temperature control unit adopted by customers in the chemical industry. It is used in the powder cleaning and recovery process and features a structure that allows for the attachment and detachment of filter paper. By consolidating the functions required across multiple processes, from stirring to powder recovery, into a single unit, it reduces the frequency of movement for operators. For more details, please refer to the "Related Links."

-

Notice of Year-End and New Year Business Days | Nitto Metal Industry Co., Ltd.

Our business hours during the year-end and New Year period are as follows: Last business day of the year: Tuesday, December 27, 2022 First business day of the new year: Thursday, January 5, 2023 Inquiries during the holiday period will be addressed sequentially starting from Thursday, January 5, 2023. We sincerely thank you for your patronage this year and look forward to your continued support in 2023.

-

[Case Study] Jacket Tank with a Stand-Alone Structure that Can be Raised and Lowered with a Lifter

We have added case studies of our products to the official Nitto Metal Industry website. This is a custom-made stainless steel tank that can be insulated, stirred, and raised, adopted by customers in the chemical industry. It will be used for dissolving and stirring chemicals in the production of new products. For more details, please see the related link.

-

[PDF document published] Troubleshooting when using stainless steel containers

A stainless steel container manufacturer has compiled common troubles and issues that may arise during the use of stainless steel containers. This document primarily explains solutions based on inquiries received from customers using Nitto Metal Industry's containers. For more details, please refer to the related catalog at the bottom of the page.

-

[Case Study] Slurry Liquid Supply Hopper

We have added product case studies to the official Nitto Metal Industry website. This is a custom-made stainless steel hopper for supplying slurry containing solid materials to a pump. A square flange viewing window has been installed on the side of the hopper so that the height of the solids in the liquid can be observed. For more details, please visit the related link.

-

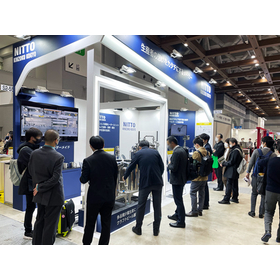

Thank you for visiting the 1st International Fermentation and Brewing Food Industry Exhibition.

We exhibited at the "1st International Fermentation and Brewing Food Industry Exhibition," which was held for the first time from November 29 to December 1. We would like to express our sincere gratitude to all the visitors who came to our booth. Thank you very much. This time, we showcased craft beer brewing tanks and stainless steel containers with temperature control and stirring functions. Please check the related links for product details.

-

[Technical Column] Worker-Friendly Exposure Measures Around Stainless Steel Tanks

The homepage "Technical Column" has been published. In places that handle powder materials and organic solvents, exposure to these substances can have health impacts, so exposure measures are necessary to prevent this. While there are measures that can be taken on the worker's side, it is important to suppress the factors that lead to exposure for workers from the equipment side. In this column, we will mainly introduce exposure measures that our company can propose around stainless steel tanks when handling powders. For more details, please refer to the "Related Links" section below.

-

Compatible with Class 6 clean rooms! Stainless steel bottle with clean pack specifications.

【PSO-CP】Heuristic Type 316L Straight Bottle (Clean Pack) ○ A stainless steel bottle (small capacity container) that has been cleaned with ultra-pure water and assembled and double-packaged in a clean room. By removing it from the outer bag, which has been exposed to the outside air, the introduction of contaminants is prevented. The liquid-contacting parts are electropolished, making post-opening cleaning tasks easier. ○ Compatible with Class 6 clean rooms! Ideal for locations that require high cleanliness, such as pharmaceutical factories and semiconductor factories. For more details about the product, please refer to the related links.

-

You can easily order stainless hoppers that are essential for equipment and production lines.

A stainless steel hopper that can be created by choosing from a variety of customization options has arrived. You can customize up to seven parts, including the inner diameter and discharge outlet. *The customizable items vary by series.

-

Mixing body that can stir without cutting a one-dan can | Leaf Tree Mixer (Bernoulli Flow Mixing Body BEAG L Type)

We would like to introduce a stirring device that can powerfully mix liquids without transferring them from a 10-liter can or a pail. It can be attached to hand mixers or drills with a shaft diameter of φ10mm or φ12mm. It can be inserted through the opening of a 10-liter can or pail (with an opening diameter of φ32mm or larger). Since it does not cut the top of the can, the risk of foreign matter contamination is reduced, and the cap can be replaced for storage after stirring. For more details, please refer to the catalog or related links.

-

Hose bracket that can be installed on the edge of the tank.

We would like to introduce a stainless steel bracket that can secure the end of a hose to the edge of a stainless steel container. There is no need to hold the hose during water injection or when adding liquid materials. You can perform other tasks while filling, which improves work efficiency. The padded type can avoid metal contact with the container. For more details, please refer to the catalog or related links.

-

[First Event] From November 29 to December 1, we will be exhibiting for the first time at the 1st International Fermentation and Brewing Food Industry Exhibition!

We will be exhibiting for the first time at the inaugural International Fermented and Brewed Food Industry Exhibition. In addition to a craft beer kettle set tailored for the processes of saccharification, boiling, and fermentation, we will showcase temperature control and stirring devices ideal for the production of fermented foods such as sweet sake and miso. We invite you to visit this inaugural exhibition and stop by our booth. Date and Time: November 29 (Tuesday) 13:00 - 18:00, November 30 (Wednesday) 10:00 - 18:00, December 1 (Thursday) 10:00 - 17:00 Venue: Tokyo Big Sight, South Exhibition Hall Entry: Registration is required ☆ Online pre-registration (recommended) or bring a downloaded invitation ticket. For more details, please refer to the related links.