news list

latest news

Regarding the internet and telephone line issues at the Yatsushiro Factory.

Due to a road collapse accident that occurred around 10 AM on January 28 (Tuesday) in the neighboring area, our Yashio factory (including the sales department) is experiencing disruptions to both inte…

91~120 item / All 502 items

-

Notice of Summer Vacation | Nitto Metal Industry Co., Ltd.

Our summer vacation period will be as follows: 【Summer Vacation Period】 From Thursday, August 11, 2022, to Tuesday, August 16, 2022. We will resume normal operations on Wednesday, August 17, 2022. Inquiries made during the vacation period will be addressed sequentially starting from Wednesday, August 17. We apologize for any inconvenience this may cause and appreciate your understanding.

-

[New Product] Lower Stirring Unit for Pharmaceutical Manufacturing

We have released a "stirring unit" that combines a stainless steel container and a stirrer. It is designed with a focus on cleanability, making it suitable for processes that particularly dislike foreign matter contamination. The container is made of rust-resistant 'SUS316L'. Its surface undergoes a treatment called 'electropolishing', which removes abrasive contaminants and creates a surface that is less likely to retain dirt and easier to clean. The stirrer is designed to float in the container using magnetic force, making it suitable for cleaning with CIP/SIP in a sterile design. It is recommended for processes that require a high level of hygiene, such as pharmaceutical manufacturing. For more details, please visit our official website.

-

[New Product] Automatic Opening and Closing with Air | Pneumatic Shutter Valve

**New Automatic Opening and Closing Type Valve for Powder and Granular Materials** An automatic opening and closing type has been added to our shutter valve series, which has been adopted in filling processes and raw material feeding processes for powders and granules. By supplying air to the air cylinder, it can automatically open and close using pneumatic pressure. It can also be linked with other equipment, making it useful for automating processes. Product Lineup: - [SHB-A] Pneumatic Shutter Valve, Double Hurl Type - [SH-A] Pneumatic Shutter Valve (Type with protruding short pipe on the lower side)

-

[New Product] Perfect for HACCP Compliance! | Stock Pot

We have registered the catalog for the new product "Stock Pot (NSF Certified)." The Stock Pot is an all-stainless steel container that is ideal for HACCP compliance. Glass containers are prone to breakage, which can lead to foreign object contamination, and plastic containers may suffer from deterioration over time, such as splintering. The Stock Pot, being made of stainless steel, is less likely to break and has excellent durability and corrosion resistance, making it perfect for HACCP compliance. The Stock Pot features a flat structure for the parts of the container and lid that come into direct contact, ensuring excellent cleanability. Additionally, it enhances cleanability by eliminating folds and curled edges on the container and lid, which are areas where dirt tends to accumulate. For more details, please refer to the catalog or visit the official website.

-

[Technical Column] Six In-House Products Used by Stainless Steel Manufacturers

The Nitto Metal Industry website has been updated with a "Technical Column." [Technical Column] Six In-House Products Used by Manufacturers of Stainless Steel Products Nitto Metal Industry's industrial stainless steel products are used in factories and laboratories across various industries, but in fact, we also use our own products internally. In this column, we will introduce some of the ways we utilize our products within the company. For more details, please check the related link.

-

[Case Study] Pharmaceutical Company Adopts! Lockable Stainless Steel Storage Container

This is a custom case of stainless steel containers used as storage containers in a pharmaceutical factory. The container is based on a band-type sanitary container commonly used in the pharmaceutical industry, with the material changed to SUS316L, and features a high-grade stainless steel interior that has been electropolished. The padlock used for locking is also made of stainless steel, making it a custom-made product filled with the client's commitment as a pharmaceutical company. For more details, please refer to the related link.

-

We will exhibit at the 24th Interphex Japan!

We will be exhibiting at Japan's largest pharmaceutical research and manufacturing exhibition, "The 24th INTERPHEX JAPAN." This will be our largest exhibition ever at Nitto Metal Industry. We sincerely look forward to your visit. If you would like to discuss or meet with us at the venue on the day, please feel free to contact us. Dates: July 13 (Wednesday) to July 15 (Friday), 2022 - 3 days Time: 10:00 AM to 6:00 PM (only on the last day, July 15, it will end at 5:00 PM) Venue: Tokyo Big Sight Booth Location: South Exhibition Hall, South 1 Hall, Raw Material Processing Zone 5-2 For details about the exhibits, please refer to the "Related Links" at the bottom of the page.

-

Thank you for visiting FOOMA JAPAN 2022.

We would like to express our sincere gratitude to all the visitors who came to the Nitto Metal Industry booth at FOOMA JAPAN 2022 (International Food Industry Exhibition). Thank you very much. At this exhibition, we showcased stainless steel products that "solve problems related to stirring and mixing." For more details about the exhibited products, please refer to the related links below.

-

We have published explanatory materials: Protecting the safety of workers! Customization to prevent near misses.

When using stainless steel containers, you may think things like, "I want to make this task easier," "I want to eliminate dangerous parts," or "I want to prevent injuries during work." In this document, we will introduce safety measures that can be achieved through "slight customization" of our products. By using stainless steel containers tailored to the specifics of your work, you can improve work efficiency and help prevent injuries.

-

We have published explanatory materials: Customization of stainless steel containers essential for factory automation.

In recent years, the trend of automation (robotization/factory automation) has accelerated in pharmaceutical and cosmetic factories. At our company, we have seen an increase in custom orders for stainless steel containers from customers who want to use them on automated production lines. By customizing stainless steel containers to match the equipment and tasks being used, we can fully utilize the performance of the equipment and solve process issues. This document introduces recommended customizations and products for stainless steel containers to be implemented in automated processes.

-

We will be exhibiting at FOOMA JAPAN 2022 (International Food Industry Exhibition)!

Nitto Metal Industry Co., Ltd., a manufacturer of stainless steel containers and mixing equipment, will be exhibiting at FOOMA JAPAN 2022 (International Food Industry Exhibition), proposing "A Rich Future Opened by Food Technology." If you would like to consult or meet with us at the venue on the day, please feel free to contact us. Dates: June 7 (Tuesday) to June 10 (Friday), 2022, for 4 days Time: 10:00 AM to 5:00 PM Venue: Tokyo Big Sight Booth Location: East Hall 1, 1K-15 For details on exhibited products, please refer to the "Related Links" at the bottom of the page.

-

Material certificates and other documents can now be downloaded from our website!

As a benefit for free members on our website, certificates for certain products are now available for download. For information about the downloadable certificates and how to download them, please refer to the "Related Links" at the bottom of this page. *There may also be certificates not listed on our website (such as mill sheets and various inspection certificates) that can be provided for a fee. If you are interested, please contact us. *Please note that there may be items not listed. Thank you for your understanding.

-

We introduce our company's features and our commitment to product creation through videos.

We introduce the features of our company, a manufacturer of stainless steel containers and mixing devices, as well as our commitment to product creation in a video. For more details, please refer to the "Related Links."

-

[Case Study] Stainless steel container with a visible capacity of 2,000ml

This is an example of a small-capacity stainless steel container for measuring solvents, adopted by customers in the chemical industry. It is equipped with a level gauge to visualize the contents. You can find more details through the related link.

-

[Technical Column] Customization of Stainless Steel Containers Essential for Factory Automation

We have published a "Technology Column" on our website. For more details, please refer to the "Related Links" section below. "Customization of Stainless Steel Containers Essential for Factory Automation" In recent years, the trend of automation (robotization/factory automation) has accelerated in pharmaceutical and cosmetic factories. We have also seen an increase in custom orders from customers who want to use stainless steel containers on automated production lines. In this column, we will introduce recommended customizations and products for stainless steel containers to be used in automated processes.

-

We have released a video on preventing excessive tightening and leaks of the Heller.

A product that can standardize the tightening torque of clamp bands when combined with a torque wrench. We have created a video explaining the torque management socket for clamp bands. For more details, please see the "Related Links."

-

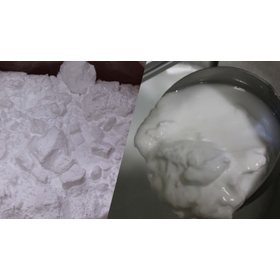

We have released a video on "Discharge of materials that are easy to settle | KTTX."

The KTTX, with a steeper bottom angle compared to the standard single taper container KTT, has an inclination of 10 degrees, while the KTT has an inclination of 3 degrees. This makes the KTTX particularly effective for discharging liquids that are difficult to expel. In this video, we tested its performance by discharging a water-soluble potato starch that tends to settle. You can watch the video via the "Related Links."

-

[Technical Column] Is it better not to use buff polishing? The commitment of a stainless steel container manufacturer.

The homepage "Technical Column" has been updated. Please check it out from the "Related Links" below. "Is it better not to perform buff polishing? The commitment of a stainless steel container manufacturer" "Buff polishing" is often done as the final finishing touch for stainless steel products. Generally, the shiny surface of stainless steel is due to buff polishing. By performing buff polishing, burrs and scratches from processing can be removed, and the surface smoothness can be improved. It results in a very beautiful appearance, which is why buff polishing is commonly performed. However, the beauty is merely "superficial." Essentially, not performing buff polishing can help maintain a cleaner state. In this article, we will explain the reasons behind this and the commitment and philosophy of Nitto Metal Industry.

-

We have released an experimental video [Customer Mixing Demo Case | Uniformity of Liquid Powder].

This is a demonstration case for pharmaceutical manufacturers considering the new introduction of a stirring temperature control unit (container + stirrer). We conducted stirring tests aimed at confirming the stirring conditions and operations during the scale-up process.

-

"I have registered a new PDF document" Read "Tips for Not Failing When Buying a Mixer" if you want to buy a mixer!

There are various models of mixers released by different manufacturers, and it is common to feel overwhelmed with the abundance of options, wondering, "Which one is good?" "Will it mix properly?" "How do I buy one?" This PDF document introduces tips for choosing a mixer that you should know when purchasing one, as well as how to buy a mixer. It is recommended for those who are responsible for purchasing a mixer for the first time or those considering getting a mixer. You can view the PDF document from the related catalog at the bottom of the page.

-

A new case study collection has been created: Stainless Steel Stirring and Temperature Control Unit Adoption Cases.

A stirring temperature control unit is a stirring device that can mix while regulating the temperature of the contents by circulating a heat transfer medium in the jacket (outer tank) of a stainless steel container. This collection of case studies introduces some examples of custom-made stirring temperature control units that have been delivered so far. For more details, please refer to the related catalog below.

-

Are the measures against foreign matter contamination thorough? "Measures against foreign matter contamination around stainless steel containers - Mixing and cleaning processes."

The PDF document has been registered with Ipros. "Measures Against Foreign Matter Contamination Around Stainless Containers - Mixing and Cleaning Processes" Stainless containers are used in areas with high hygiene standards. In such environments, there is often a strong focus on measures against foreign matter contamination. This PDF document introduces "measures against foreign matter contamination around stainless containers" during the mixing and cleaning processes. Since it is a PDF, please feel free to use it for internal circulation as is.

-

Are the measures against foreign matter contamination thorough? "Measures against foreign matter contamination around stainless steel containers - Storage and Feeding Processes -"

The PDF document has been registered with Ipros. "Measures Against Foreign Matter Contamination Around Stainless Containers - Storage and Input Processes" Stainless containers are characterized by their resistance to rust. Environments that use such stainless containers often have high hygiene standards and robust measures against foreign matter contamination. This PDF document introduces "Measures Against Foreign Matter Contamination Around Stainless Containers" in the storage and input processes. Since it is a PDF, please feel free to use it for internal circulation as is.

-

We have updated customer feedback regarding the small-batch production of craft beer.

To meet the demand for small-scale production of craft beer, we have introduced Nitto Metal Industry's custom-made stainless steel containers. We have created brewing equipment using 100L size cylindrical containers and published customer testimonials about our original beer manufacturing service aimed at restaurants and wedding favors. For more details, please refer to the "Related Links" section below.

-

We have released an experimental video on the dispersion of powder that has clumped due to humidity.

This is an inquiry and demo case from a customer considering the new introduction of a mixing unit (container + mixer). They mentioned that the workload for dissolving powder that has partially clumped due to moisture is high, and they sought advice on process improvement. We verified whether we could replicate the same process and reduce the workload.

-

We have released a product introduction video for the [Powder Recovery Stainless Steel Container].

The "Powder Recovery Stainless Steel Container" FK-CTH series is active in the recovery process of powder particles discharged from devices. In addition to being able to choose from four mounting shapes according to the connection method, we accept flexible customization from one unit, including changes in shape and size, tank capacity, and material. This video introduces the features and product lineup of the powder recovery stainless steel container. You can watch the video from the related link.

-

The PDF catalog for the peephole (sight glass) is ready!

This is a PDF document summarizing the product lineup of "viewing windows" manufactured by Nitto Metal Industry, which are used as sight glasses mounted on stainless steel tanks. Please refer to the "Related Catalogs" at the bottom of the page. This document introduces a total of 13 types of products with both hygienic connection (NMB series/NM series) and flange connection. It also showcases custom-made achievements for the viewing windows. Various specifications can be changed, such as size and material, so please feel free to contact us.

-

We have released a video of laser marking processing.

Some of our stainless steel products have their model numbers and other information printed using laser marking. Additionally, you can choose to add laser marking as an option when ordering our products. In this video, we will introduce the benefits of laser marking and show the processing involved. You can watch the video via the related link.

-

[New Product] Supports Powder Feeding | Dust Collection Hood with Legs

By installing this product at the top of the container where the lightweight and easily airborne powder is being added, it allows for the collection of the powder that rises during the addition process, thereby reducing cleaning time and improving the hygiene of the workspace. The large hood, which efficiently collects dust, can be connected to a dust collector (sold separately), and by replacing the container, it can accommodate multiple containers.

-

[New Product] Custom Hopper Made to Order

A stainless steel hopper that can be created by choosing from a variety of customization options has arrived. You can customize up to seven parts, including the inner diameter and discharge outlet. *The customizable items vary by series.