What is an Indium Mirror Coating System?

What is an indium mirror coating system?

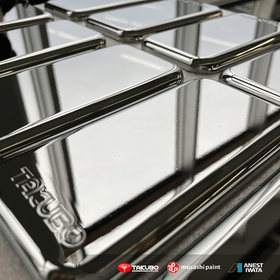

The indium mirror coating system is a dedicated coating process optimized for forming indium-based high-reflectivity mirror films. The standard process consists of a 3-coat, 3-bake structure (repeating application and drying three times), and the management of film thickness, heating conditions, and environmental control during each step significantly affects optical properties and adhesion. In particular, parameters such as the concentration of fine particles, temperature and humidity, and electrostatic environment within the painting booth influence the final film quality (reflectivity, durability), making the formation of the coating in a clean and stable environment extremely important. **Features and Benefits of Indium Mirror Coating** - A new metal color spray method that achieves reduced environmental impact: A coating system using spray painting technology as a replacement for traditional plating processes. - Compatibility with various materials: Forms a highly adhesive and uniform film on various substrates such as stainless steel, resin, and glass. - Excellent radio wave transmission characteristics: Equipped with radio wave transmission performance suitable for radar and communication devices, differing from optical high-reflectivity films, making it ideal for sensor-related applications. - Automation compatibility and multilayer coating: Can be integrated into automated lines in conjunction with Takubo's painting robots. Durability can be adjusted through multilayering from the base layer to the protective layer.

basic information

The indium mirror coating system is a dedicated multilayer coating process developed to achieve a high-reflectivity mirror film primarily composed of indium. The process consists of 3 coats and 3 bakes, where each layer undergoes application → drying → heat curing (bake) to form a coating with excellent adhesion, heat resistance, and optical performance. ■ Bake Conditions (Reference Values) ProcessTemperatureTimePurpose 1st Bake (after primer): 80–100 ℃10–15 minutesSolvent evaporation and mild curing of the base layer 2nd Bake (after intermediate coat): 120–150 ℃15–20 minutesStrengthening adhesion of the intermediate layer and improving smoothness 3rd Bake (after top coat): 150–180 ℃20–30 minutesComplete curing of the final film and stabilization of mirror finish *Conditions can be adjusted according to the heating method (hot air circulation / infrared / gas type, etc.) and work material. ■ Environmental Management Requirements (Recommended) Cleanliness: Class 10,000 (ISO 7) or better Temperature: 22–26 ℃ Relative Humidity: 45–60 % Static Electricity Measures: Conductive flooring and ionizer installation recommended *For more details, please refer to the materials. Feel free to contact us with any inquiries.

Price information

Please contact us.

Delivery Time

Model number/Brand name

Indium Mirror Coating System

Applications/Examples of results

*For more details, please refer to the materials. Feel free to contact us as well.*

Line up(4)

| Model number | overview |

|---|---|

| 3R3C Line Dancer 4gun 8top | This is a painting system consisting of three robots, each responsible for one coat. It has a short movement time, high productivity, and is suitable for mass production. It features a 3R3C line dancer with a four-gun, eight-top automatic painting system (for mass production). Each robot is equipped with four guns, and the transport device (table) has eight tops. |

| 3R3C Swampro 2gun 4top | Three robots will handle three coats (one robot per color). It is a compact type of semi-mass production system for plating and painting. The Swan Pro is a standalone autonomous robot, and the transfer is managed by a double turntable equipped with the Swan Pro. It is separated from the conveyor, and the painting object transport device, Co_Swan, is responsible for handling, which keeps the line clean and prevents defects in painting such as spots. This is the 3R3C Swan Pro 2-gun 4-top automatic painting system (for semi-mass production). |

| 1R3C Line Dancer Turret 3Gun 4top | A single robot processes three coats (one robot, three colors). It is a production line for small lots and a variety of products with plating and painting. It is equipped with a turret gun unit that can be fitted with three guns, allowing for quick color changes. This is a compact painting system. 1R3C line dancer with a 3-gun turret and 4-top automatic painting system (for small lots and a variety of products). One robot is equipped with three guns and a conveyor device (table) with four tops. |

| 1R3C Swampro Turret 2Gun 4top | - Batch painting system: A batch painting system that processes 3 coats (3 colors with 1 robot). After each coat, it goes to a drying oven operated by a worker. This system is designed for small-scale production and helps to keep initial costs down. 1R3C Swan Pro 2 Gun Turret 4 Top Batch Painting System (for small quantity and diverse products): Equipped with 2 guns on 1 robot and a conveying device (table) with 4 tops. |

catalog(10)

Download All CatalogsNews about this product(2)

-

Emblem Indium Coating Takubo Engineering

Takubo Engineering Co., Ltd. has applied an indium mirror coating to the emblem of the Anest Iwata Racing Lexus Racing vehicle. The Super GT-300 race features vehicles that have been customized from commercial cars to racing specifications, with Anest Iwata Co., Ltd. participating as Anest Iwata Racing. The emblem of this vehicle has been treated with an indium mirror coating that reproduces a chrome-like paint film using newly developed indium paint. Compared to traditional chrome plating production, this method consumes less paint, reduces painting costs, and significantly cuts down on waste disposal costs such as sludge fees, thereby improving environmental performance. The chrome-like paint film is recreated using a spray application. The indium mirror coat is realized through the Indium Mirror Coating System, achieved through a three-coat, three-bake process. This was developed through a collaboration between Musashi Paint Co., Ltd., Anest Iwata Co., Ltd., and Takubo Engineering Co., Ltd. For inquiries, please contact the Sales Engineering Department of Takubo Engineering Co., Ltd., Indium Mirror Coating System section, TEL: 0475-50-0211, or visit the Takubo Web inquiry page.

-

Indium mirror coating<br> Anest Iwata Racing on Lexus RC emblem

Iridium mirror coating has been applied. Anest Iwata Racing, participating in the Super GT-300 race, will compete with the Toyota Lexus GT at the Fuji Speedway for the 'Super GT-300 Round 4' on August 3, 2025. The iridium mirror coat has been applied to the rear Lexus emblem of the vehicle. It is a chrome-like color coating. For subsequent races, the color will be changed for each participation. The color plan for future races includes changing the color for each race and applying a matte iridium mirror coating as well. ---------------------------------------------------- For inquiries about the Iridium Mirror Coating System, please visit https://www.takubo.co.jp/contact/ or contact the Iridium Mirror Coating System department at Takubo Engineering Co., Ltd. Public Relations, Takubo Engineering Co., Ltd.

Recommended products

Distributors

Takubo Engineering has established technology in painting and is independently developing a painting system that reduces running costs and enhances profit effectiveness. We are developing solutions to meet the demands of improving quality, lowering painting costs, and increasing profits comprehensively and simultaneously. Thinking because it does not exist in the world Takubo Engineering independently thinks of systems that meet the needs of painting management because there are none available. We are also pursuing better ways of painting systems. ◎ We independently develop and sell painting-specific robots and painting systems. In addition to the hanging mobile explosion-proof line dancer, we have newly added a self-standing explosion-proof swan robot to our lineup. ◎ Main products: Explosion-proof painting robots: Line dancer, Swan Hot air drying furnace: Dry Tech Painting booth: Oil Booth Conveyor line: Dragon Line Explosion-proof paint supply system: Syringe pump system Automatic spray gun: Scotch Gun Small explosion-proof AC servo motor Hose-less robot IH drying system Clean room dedicated to painting Special ceramics paint UV painting system, drying system, and other painting systems