news list

61~90 item / All 109 items

-

◆Yoshida SKT Co., Ltd.◆ NEW "Urethane Coating 'CD9000 Standard Grade'" has been released.

Wear-resistant and noise-reducing! Can be processed at room temperature. All coatings are of the room temperature curing type and can be processed on chemical wood and plastic. "Urethane Coating CD9000" is a room temperature curing type coating that excels in wear resistance and soundproofing, and can be processed on any material except liquids and gases. For more details, please check the product site.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Published 'Advantages and Disadvantages of PTFE Lining - Lining Explanation Materials Available'."

We have published the advantages, disadvantages, and features of PTFE lining. We are currently offering detailed materials explaining fluoropolymer lining. Please be sure to check it out along with our product site. 【Contents of the materials】 1. What is lining? 2. Materials and characteristics of lining 2-1. Rubber materials 2-2. Resin materials 2-3. Glass materials 3. Chemical resistance of fluoropolymer lining 3-1. What is chemical resistance? 3-2. Effects of chemicals on resin 3-3. Mechanism of chemical resistance in fluoropolymers 3-4. Examples of applications utilizing chemical resistance 4. Methods and materials for fluoropolymer lining 4-1. Sheet lining 4-2. PFA lining 4-3. Comparison of characteristics by lining method If you are interested, please download the materials and check them out.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Construction Procedure for Fluororesin Sheet Lining - Explanation Materials for Lining Available" has been released.

Here is an introduction to the processing procedures of fluoropolymer sheet lining, which is not widely known. We are currently offering detailed materials explaining fluoropolymer lining. Please be sure to check them out along with our product site. 【Contents of the materials】 1. What is lining? 2. Materials and characteristics of lining 2-1. Rubber materials 2-2. Resin materials 2-3. Glass materials 3. Chemical resistance of fluoropolymer lining 3-1. What is chemical resistance? 3-2. Effects of chemicals on resins 3-3. Mechanism of chemical resistance in fluoropolymers 3-4. Examples of applications utilizing chemical resistance 4. Methods and materials for fluoropolymer lining 4-1. Sheet lining 4-2. PFA lining 4-3. Comparison of characteristics by lining method If you are interested, please download the materials and check them out.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Benefits and Drawbacks of PFA Lining - Presentation Materials on Lining Explained" has been released.

Publicizing the advantages and disadvantages of PFA lining. We are currently offering detailed materials explaining PFA lining. Please be sure to check it out along with our product site. 【Contents of the materials】 1. What is lining? 2. Materials and characteristics of lining 2-1. Rubber materials 2-2. Resin materials 2-3. Glass materials 3. Chemical resistance of fluororesin lining 3-1. What is chemical resistance? 3-2. Effects of chemicals on resin 3-3. Mechanism of chemical resistance in fluororesin 3-4. Examples of applications utilizing chemical resistance 4. Methods and materials for fluororesin lining 4-1. Sheet lining 4-2. PFA lining 4-3. Comparison of characteristics by lining method If you are interested, please download the materials and check them out.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Overview of Fluororesin Sheet Lining Processing - Lining Explanation Materials Available" has been released.

Here is an overview of the lesser-known fluoropolymer sheet lining process. We are currently offering detailed materials explaining fluoropolymer lining. Please be sure to check it out along with our product site. 【Contents of the materials】 1. What is lining? 2. Materials and characteristics of lining 2-1. Rubber materials 2-2. Resin materials 2-3. Glass materials 3. Chemical resistance of fluoropolymer lining 3-1. What is chemical resistance? 3-2. Effects of chemicals on resins 3-3. Mechanism of chemical resistance in fluoropolymers 3-4. Examples of applications utilizing chemical resistance 4. Methods and materials for fluoropolymer lining 4-1. Sheet lining 4-2. PFA lining 4-3. Comparison of characteristics by lining method If you are interested, please download the materials and check them out.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Published measures against mold release troubles in injection molding machines: ultra-durable fluorine-based organic coating."

An astonishing durability that transcends fluoropolymer coatings! Surface treatment suitable for applications with mechanical loads. Ultra-durable fluorine-based organic coating system 'Bicoat(R)' "Surface treatment of inorganic materials with hardness and wear resistance, such as metals and ceramics" + "Surface treatment of organic materials with release and slip properties of fluorine and silicone" With our unique surface treatment technology, We have achieved an ideal durability of "release" + "sliding" + "wear resistance" in our coating system. *Product catalog and case study materials available!

-

◆Yoshida SKT Co., Ltd.◆ NEW "Improving the release properties of injection molding molds! Ultra-durable fluororesin coating 'Bicoat' has been released."

Improving the release properties of injection molding molds. A fluorine-based coating system suitable for applications with mechanical loads that have astonishing durability. 'Bicoat(R)' By combining surface treatment technologies for inorganic materials and organic materials, this coating system achieves the ideal functions of "release properties" + "sliding properties" + "wear resistance." *Product catalog and case study materials available upon request!

-

◆Yoshida SKT Co., Ltd.◆ NEW "Case studies of coating technology specialized in thermal welding" have been released.

CHC (Ceramic Hard Coat) is a new type of fluoropolymer coating that achieves both non-stick properties equivalent to standard fluoropolymer coatings and high film hardness at elevated temperatures. ■ Examples of Surface Treatment Applications - A case where high-temperature release and long-term durability were achieved in the thermal welding process of filter cases. - A case where the release effect from processing on thermal welding plates lasted three times longer than PTFE coatings. - A case that resolved the "peeling" and "blistering" issues of fluoropolymer coatings on resin welding plates. - A case that eliminated adhesive adhesion and peeling at high temperatures, which could not be resolved with PTFE coatings. *You can download a PDF summarizing detailed case studies and product information. Please contact us for more information.

-

◆Yoshida SKT Co., Ltd.◆ NEW "【New Technology】Surface Treatment Case: Release Effect for High Temperatures Lasts 3 Times Longer!" has been published.

Successfully improved the high-temperature durability of conventional fluoropolymer coatings with CHC technology! Introducing a surface treatment that has tripled the lifespan of heat-welded plates.

-

◆Yoshida SKT Co., Ltd.◆ NEW "【Surface Treatment Case Study】 Streamlining the Lithium-Ion Battery Manufacturing Process!" has been released.

Preventing adhesion of adhesive tape used in the manufacturing of lithium-ion batteries. Achieving both extended maintenance periods and prevention of line stoppages with surface treatment suitable for cutting tools. We would like to introduce an improvement case for cutting equipment of insulating tape used in the production of lithium-ion batteries. ■ Key Issues - Problems arose with adhesive material adhering to the cutting blade, causing line stoppages. - The cutting tool is of the shear type, using two blades like scissors. - Frequent cleaning was required to prevent line stoppages, resulting in decreased production efficiency. * There is also a collection of case studies for solving cutting process issues. Recommended for those looking to resolve adhesive problems with cutting blades.

-

◆Yoshida SKT Co., Ltd.◆ NEW "We have launched the official Yoshida SKT blog to share our expertise in fluororesin and surface treatment technology!"

We provide information that helps solve the challenges faced by production equipment engineers! "Coating MAGAZINE" is an information media related to surface treatment and coating developed by the surface treatment technology manufacturer Yoshida SKT. We feature numerous articles, including functional explanations such as "Explaining the Non-Stick Properties of Teflon Fluororesin," as well as knowledge surrounding surface treatments like plating, anodizing, and blackening, and explanations about "What is PTFE? - Differences from Teflon Resin." We share information that is useful for overcoming the challenges faced by production equipment engineers. Please take a look!

-

◆Yoshida SKT Co., Ltd.◆ NEW "Strong against chemicals! What is the chemical resistance of fluororesin?" has been released.

What is the representative characteristic of Teflon fluoropolymer, "chemical resistance"? What kind of characteristic is it? I will explain by comparing it with the representative plastic polyethylene. ーーーーーーーーーーーーーーーーーーーーーーー ■INDEX 1. What is chemical resistance? 2. The impact of chemicals on resins 3. Reasons why Teflon fluoropolymer excels in chemical resistance 4. What can be done using chemical resistance ーーーーーーーーーーーーーーーーーーーーーーー For more details, please download the materials or visit the product page.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Fluororesin Coating 'Corrosion Resistance of Thick Film Coating'" has been released.

Teflon fluoropolymer, used for corrosion-resistant lining to protect substrates from chemicals. This explains the corrosion resistance of fluoropolymer thick film coatings. ーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーー 1. What is corrosion resistance? 2. How to prevent corrosion 3. Corrosion resistance of Teflon fluoropolymer coatings 4. Characteristics of Teflon fluoropolymer coatings for corrosion-resistant applications 4-1. No pinholes or defects in the coating film 4-2. Thickening of the coating film 5. What can be achieved by utilizing the corrosion resistance of Teflon fluoropolymer coatings ーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーーー For more details, please download the materials or visit the product page.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Fluororesin Coating 'What is the Water and Oil Repellency of Fluororesin?'" has been released.

What are the representative properties of Teflon fluoropolymer coatings, "water repellency and oil repellency"? What kind of characteristics are they? We will provide materials that outline their mechanisms and methods of verification. ■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□ 1. What are water/oil repellency? 2. Reasons why Teflon fluoropolymer excels in water/oil repellency ~Surface free energy~ 2-1. What is surface free energy? 2-2. The relationship between water repellency and surface free energy 3. Methods to verify water/oil repellency ~Contact angle~ 4. What can be done using water/oil repellency? ■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□ For more details, please download the materials or visit the product page.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Coating Performance Measurement Service" has been featured in the Nikkan Kogyo Shimbun.

On January 19, the Nikkan Kogyo Shimbun featured our "Coating Performance Measurement Service." To meet the needs of those who want to verify the effectiveness before coating, Yoshida SKT measures the coating surface using our unique know-how. "I want to test the effectiveness of the coating with materials produced in-house." "I am considering introducing a coating but am struggling with how to select it." To address such concerns, we propose measuring coating performance with our unique know-how, allowing for comparison and consideration before introducing a coating. Please feel free to consult us about preparing sample pieces. ▼ You can download the brochure from the link below!

-

◆Yoshida SKT Co., Ltd.◆ NEW "Silicone Release Agent and Silicone Coating" has been released.

What is a release agent? A release agent used for mold release. Even release agents that are considered versatile can have unexpected challenges! We will introduce silicone coatings that are effective for the challenges of silicone release agents.

-

◆Yoshida SKT Co., Ltd.◆ NEW "【Surface Treatment Case】 Reducing Line Downtime by Preventing Rubber Adhesion!" has been released.

Coating to prevent sticking inside the vacuum nozzle reduces maintenance work. Prevents nozzle clogging and improves productivity! 【Issues Addressed】 - Reduction of cleaning time - Increased productivity - Cost reduction 【Adopted Coating】 In experiments measuring release torque with strong tape, the force required to peel off was nearly zero compared to other coatings! It can maintain water and oil repellency and slip properties even with solvent cleaning! Mold Release Silicone (MRS series) exhibits excellent release properties against sticky substances and adhesive tapes, achieving top-level solvent resistance, film hardness, and heat resistance. <Reasons to Choose This Product> - Reduces sticking when cutting adhesive materials - Expected increase in productivity during cutting processes - Release effect lasts long without diminishing even with solvents *For more details, please download the catalog.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Coating Performance Measurement Service" has been featured in the Nikkan Kogyo Shimbun.

On December 7th, the Nikkan Kogyo Shimbun featured our "Coating Performance Measurement Service." To meet the needs of those who want to verify the effectiveness before coating, Yoshida SKT measures the coating surface using our unique know-how. "I want to test the coating effectiveness with materials produced in-house." "I am considering introducing coating but am struggling with the selection process." To address such concerns, we offer measurement of coating performance using our unique know-how, allowing for comparison and consideration before introducing coatings. Please feel free to consult us about preparing sample pieces. ▼ You can download the brochure from the link below!

-

◆Yoshida SKT Co., Ltd.◆ NEW "Explaining the Non-Stick Properties of Teflon Fluoropolymer! Why Doesn't it Stick?" has been released.

What is the property of non-stickiness? Why do food items not stick to Teflon-coated frying pans? We present a document explaining non-stickiness that answers such questions! Teflon fluoropolymer, known for its Teflon coating and fluorine coating. What mechanism allows it to have the characteristic of being difficult for things to stick? This is a three-part document explaining non-stickiness. ■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□ INDEX 1. The property of non-stickiness 2. Reasons why Teflon fluoropolymer excels in non-stickiness 2-1. High repellency 2-2. Low affinity 2-3. Chemically stable molecular structure 3. Examples of solutions utilizing non-stickiness - Case studies - ■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□■□ For more details, please download the document or visit the product page.

-

◆Yoshida SKT Co., Ltd.◆ NEW "【Surface Treatment Solution Case】 Achieving both high-temperature release and long lifespan with thermal welding type!" has been released.

Improving the thermal fusion process of the filter case through surface treatment. We will introduce coating examples that achieve reduced stringing and extended lifespan with heat-resistant fluorine coating.

-

◆Yoshida SKT Co., Ltd.◆ NEW "【Case Study Presentation】 We have published 'Improvement of the Transport Process with Anti-Sticking Coating'."

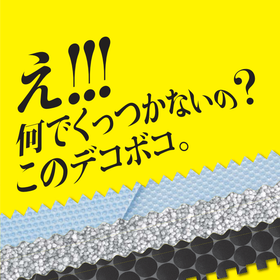

Waste hidden in conveying devices and processes. With convex coating, why not start your improvement now for "profit enhancement" and "productivity increase"? [We are giving away a collection of case studies on process improvement through coating.] Yoshida SKT's unique convex coating, which excels in "anti-stick and slip properties," will improve your conveying processes and contribute to profit enhancement. For more details, please take a look at our related products.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Surface Treatment Technology 'Improving Production Equipment for CFRP' *Materials are currently being distributed."

Production process of CFRP laminated with epoxy resin. Improve production efficiency with surface treatment technology that excels in release properties! Also solves issues related to release agents. Yoshida SKT specializes in functional surface treatments that provide a "non-stick function" to the surfaces of equipment and components, solving problems where highly adhesive materials "stick" or "adhere" to molds and surrounding equipment, hindering production or reducing production efficiency. With Yoshida SKT, improve the CFRP production process with surface treatment technology. For more details, please see related products.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Coating Performance Measurement Service New Brochure" has been released.

We have prepared a new brochure for our "Coating Performance Measurement Service," which has been well received by our customers since the start of the service. To meet the need of those who want to verify the effectiveness before coating, Yoshida SKT measures the coating surface using our unique know-how. If you want to "try the effectiveness of coatings with materials produced in-house" or if you are "considering the introduction of coatings but are unsure of how to select them," we propose measuring coating performance with our unique know-how to facilitate comparison and consideration before introducing coatings. Please feel free to consult us regarding the preparation of sample pieces.

-

◆Yoshida SKT Co., Ltd.◆ NEW "【Surface Treatment Technology】 Unique convex surface treatment creates non-stick and release properties" has been released.

With our unique surface treatment technology, we enable the prevention of sticking for particularly sticky materials such as molten plastic, labels, adhesive tapes, and raw rubber! We have prepared a series that demonstrates excellent non-stick and release properties specifically for sticky materials like adhesives, molten resins, and adhesive tapes. *Product documentation available.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Surface Treatment Technology: What is the Difference Between 'Silicon' and 'Silicone'?" has been released.

Silicone," which excels in non-stick and release properties. Explaining the differences from the easily confused "silicon." "Silicone coatings," which excel in non-stick and release properties, are often referred to as "silicon coatings." Here, we will introduce the differences between "silicon" and "silicone," as well as the superior release properties of "silicone coatings.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Nano Coating Technology Ultra-Thin Film 'Surface Treatment Technology' 'TC-10S'" has been released.

The surface treatment technology for ultra-thin films, "Nano Process TC-10S," enables nano-coating with a surface treatment technology for ultra-thin films of less than 100μm, excelling in precision, visible light transmittance, water repellency, and oil repellency. *Product documentation available.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Surface Treatment Technology 'Alloy with Excellent Strength + Coating with Superior Non-Stick Properties'" has been released.

A surface treatment technology that imparts high hardness and non-stick properties to the surfaces of resins and metals! Introducing a revolutionary non-stick treatment that maintains the flexibility of the processed materials and can be applied to rubber and curved surfaces. *Product documentation available.

-

◆Yoshida SKT Co., Ltd.◆ NEW "Surface Treatment Technology 'Ultra-Durable Fluorine-Based Organic Coating System'" has been released.

Amazing durability that surpasses fluoropolymer coatings! A coating system suitable for applications with mechanical loads. *Product catalog and case study materials available!

-

◆Yoshida SKT Co., Ltd.◆ NEW "The maintenance period has increased by 20 times! Continuous cutting of PP sheets *Case study materials available" has been released.

Non-stick coating suitable for cutting blades. A coating that extends the maintenance cycle by 20 times. *Case studies on improving blade adhesion issues are available. We will introduce a case from the process of cutting thin PP sheets, such as those used for clear files. ■Key Issues - Problems arise when PP sheets stick to the cutting blade, causing the line to stop. - The blade type is a shearing type with two blades, like scissors. - When PP adheres, the cutting surface becomes rough, leading to product defects. *There are also case studies available for solving cutting process issues. Recommended for those who want to resolve cutting blade adhesion problems.

-

◆Yoshida SKT Co., Ltd.◆ NEW "【Surface Treatment Case】 Improved Release Properties of Heat Plates for Tray Sealers!" has been published.

[Food Industry Case Study] Improved Non-Stick Properties of Welded Plates with Special Fluoropolymer Coating! Measures to Prevent Adhesion of Films that Stick Even with Fluoropolymer Coating We present a case of a non-stick coating that solved the sticking issues of molten films that could not be resolved with fluoropolymer coatings.