熱可塑性コンパウンド用添加剤:BYK-MAX CT 4255

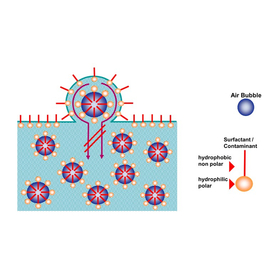

フィルムや自動車用途などの熱可塑性コンパウンドの機械物性とガスバリア性能を改善する有機修飾フィロケイ酸塩(クレイ材)フィラー

BYK-MAX CT 4255 引張強度などの機械的物性やガスバリア性を向上する熱可塑性コンパウンド用添加剤として設計されている無機フィラーの一種。ガスの種類によっては透過度を最大40%減少させることができます。独自の有機修飾により、加工時に高い熱安定性を示します。

基本情報

BYK-MAX CT 4255 製品データ 組成:有機修飾層状ケイ酸塩 密度 (25 °C): 1.88 g/ml 水分含有量: <3 % 平均乾燥粒径: <40 μm (d50) 色: オフホワイト

価格情報

価格はお問合わせ下さい。

納期

型番・ブランド名

BYK

用途/実績例

推奨用途 BYK-MAX CT 4255は 、熱可塑性樹脂に使用することができます。ポリアミドやポリエステルなどのエンジニアリング樹脂との使用に特に適しています。想定用途は自動車部品、バリア包装、難燃性コンパウンドなどが挙げられます。 推奨添加量;全配合に対して添加剤として、3-5 % 添加方法 添加剤の最適な分散および剥離を達成するために、熱可塑性コンパウンドに配合する場合には、同方向回転二軸押出機またはBUSS連続混練機の使用を推奨します。コンパウンドの際には、できるだけ長い押出ユニット(>40L/D)と高い分散性能を有するスクリュー形状を選択することが有効です。添加剤の圧縮を回避するために、可能であればサイドフィードを介して、既に溶融したポリマーに添加してください。

カタログ(6)

カタログをまとめてダウンロードこの製品に関するニュース(1)

おすすめ製品

取り扱い会社

ビックケミー・ジャパン株式会社は、塗料・添加剤・測定機器の 輸入・卸売・サービスを行っております。 様々な適用分野にわたる機能性添加剤および 試験機器のリーディングサプライヤーとして、皆様の製品開発や 課題を解決するためのソリューションをご提供いたします。 ご要望の際はお気軽にお問い合わせください。