[Tank Roof Repair Case Study] Repairing the distortion and cracks in the tank's deck plate.

Leak repair of floating roofs using the "Resin Patch Method" for tank roof repair! No welding work required, can be performed during storage. *Case study materials available.

Tank roof repair can be performed during storage as it does not require welding work. It uses a special repair material that maintains flexibility even after curing. It is suitable for leaks from decks with movement that cannot be adequately followed by iron cement or hardening putty. 【Features】 ■ Construction during storage - Can be applied while the contents are still stored. ■ Follows deck distortion - Can follow the distortion of the deck without cracking, allowing for long-term leak prevention. ■ Strong adhesion - Can be applied over weld seams, vertical surfaces, areas with insufficient surface treatment, and temporary repairs made by customers, demonstrating excellent adhesion. *For more details, please refer to the PDF materials or feel free to contact us.

basic information

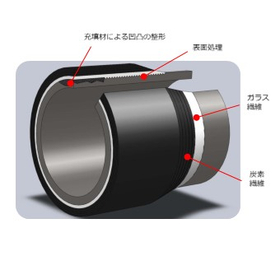

[Repair Method] ■ Surface Treatment ■ Temporary Fixing ■ Resin Coating ■ Glass Fiber Lamination ■ Surface Protective Coating *For more details, please refer to the PDF document or feel free to contact us.

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

Related Videos

catalog(5)

Download All Catalogs

Recommended products

Distributors

Fujifarmanite was established in 1978 as a specialized company for leak repair through a joint venture between Fuji Electric Construction Co., Ltd. (now Fuji Electric E&C Co., Ltd.) and the British company Farmanite. The "Leak Seal" provided by Farmanite addresses leaks of various fluids (steam, air, oil, gas, etc.) in heat sources, power sources, and product manufacturing processes, and is widely used across various industrial sectors. From the perspective of plant maintenance, we have also launched new services such as "Composite Repair," aimed at restoring the strength of thinned pipes, and "Farmaise," which opens stuck valves due to vibration. Our excellent technicians provide high-quality services using the unique technology of the British company Farmanite.