Types and Examples of High-Performance FPC [Special Bumps, Long and Ultra-Fine, High Flexibility]

Attention those struggling with cost reduction and space-saving for flexible printed circuit boards (flexible substrates)! We can provide optimal proposals tailored to your needs!

This document summarizes the types and applications of high-performance FPCs. High-performance FPCs are capable of solving various challenges such as cost reduction and space-saving. In this document, we introduce the features and application examples of special bumps, long and ultra-thin FPCs, and highly flexible FPCs. More detailed information is also available, so please take a moment to read through it. 【Contents】 ■ Types of high-performance FPCs ■ Features ■ Application examples *For more details, please refer to the PDF document or feel free to contact us. #ShortLeadTime #MassProduction #Flex #FPC #FlexibleCircuitBoard #FlexiblePrintedCircuitBoard #CircuitBoard #PrintedCircuitBoard #Special #UltraThin #Flexible

basic information

#ShortLeadTime #MassProduction #Flex #FPC #FlexibleCircuitBoard #FlexiblePrintedCircuitBoard #CircuitBoard #PrintedCircuitBoard #Special #UltraThin #Flexible

Price range

Delivery Time

Applications/Examples of results

For more details, please refer to the PDF document or feel free to contact us.

catalog(17)

Download All CatalogsNews about this product(7)

-

[Press Release from Taiyo TechnoRex] Regarding the Improvement of High-Density Wiring Formation Technology Using the Patterned Beer Fill Method

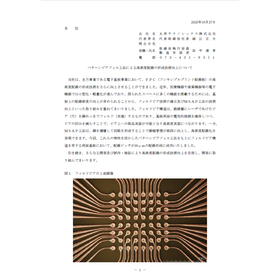

Our company has further improved the technology for forming high-density wiring in our core business of electronic substrates, specifically in flexible printed circuit boards (FPCs). In recent years, electronic devices such as medical equipment and industrial machinery have been advancing in miniaturization and lightweight design. To incorporate many functions into limited space, there is a demand for increased wiring density on the substrate. Therefore, we have been working on establishing filled via technology and improving the M-SAP method. The filled via structure involves filling vias (holes) made by laser in the insulating layer with copper plating, ensuring electrical connections on both sides of the substrate while reducing the recesses of the vias, which allows for component mounting on the vias and leads to high-density mounting. On the other hand, the M-SAP method significantly improves line width management by laminating copper to form circuits, enabling high-density wiring. This time, based on the pattern via fill method that leverages these characteristics, we successfully formed wiring with a pitch of 30μm on a double-sided substrate with a filled via structure. We will continue to aim for further improvements in high-density wiring formation technology through ongoing development, prototyping, and verification.

-

【TTL_Exhibition Participation Information】JPCAShow2025 'Newly Developed Topics.'

◆FPC (Flexible Printed Circuit Board)◆ ~Tayo Technorex's Strengths in the FPC Manufacturing Process~ The manufacturing of FPC requires multiple critical processing steps. Improving the "strengths" of each process directly leads to advancements in technology and quality, as well as new product development. This time, we will introduce the "strengths" we have cultivated over many years in each process! <Design> Circuit design, artwork, S-parameter analysis <Layer Connection> Build-up FPC, filled vias, small-diameter vias <Circuit Formation> MSAP method, thin copper, thick copper <Insulation Treatment> High-precision openings ±20μm, LCP coverlay <Surface Treatment> Standard NiAu to special plating options (Ni-Pd-Au, direct Au, etc.) <Post-Processing> High-precision outline processing ±50μm, diverse tools <Assembly> Solder mounting, ACF bonding, wire bonding, ultrasonic joining, EMS support ◆Various Substrates and Ceramic Material Systems◆ Introduction of AI technology, final appearance inspection equipment, and electrical testing equipment ◆Efficiency and Automation◆ Proposals for utilizing FA and collaborative robots

-

Experience Taiyo Technorex's FPC at Flex's social study tour, Nepcon Japan 2025!

◎FPC (Flexible Printed Circuit Board): Under the theme of "Discovering Applications for FPC," you can experience the characteristics of FPC in four zones: lightweight, flexible, fine, and special. 1. Comparison of weight between rigid boards and FPC 2. FPC that you can actually touch and bend 3. Reduction of board area due to high-density wiring 4. FPC with special features such as transparent, high-frequency, and pressure-resistant types Additionally, we are also showcasing next-generation circuit technologies such as stack vias and via fills. It's not just about FPC! We have live demonstrations of 'FA Automation' and the latest appearance inspection system using AI technology! ◎FA Automation: By achieving teaching-less automation through visual feedback control, we eliminate the burden of calibration and realize high-precision, high-speed operation. We have prepared a demonstration for the transport of rigid boards. ◎The latest final appearance inspection system, the AI system 'TY-VISION XAIS,' is now in Chapter 2! In addition to improving efficiency by reducing false positives in the final appearance inspection process, it also supports defect detection using AI. It is effective for defects with minimal brightness differences that are difficult to detect with inspection devices, even though they can be identified visually.

-

Experience Taiyo Technorex's FPC at Flex's social study tour, Nepcon Japan 2025!

◎FPC (Flexible Printed Circuit Board): Under the theme of "Discovering Applications for FPC," you can experience the characteristics of lightweight, flexible, fine, and special FPCs in four different zones. 1. Comparison of weight between rigid boards and FPCs 2. FPCs that you can actually touch and bend 3. Reduction of board area due to high-density wiring 4. FPCs with special features such as transparent, high-frequency, and pressure-resistant types Additionally, we are also showcasing next-generation circuit technologies such as stack vias and via fills. Not only FPCs! We also have a live demonstration of the latest appearance inspection system using AI technology in the fields of FA and automation! ◎FA Automation: By achieving teaching-less operation through visual feedback control, we eliminate the burden of calibration and realize high-precision, high-speed automation. We have prepared a demonstration of rigid board transport and are waiting for you. ◎The latest final appearance inspection system, the AI system "TY-VISION XAIS," is now in Chapter 2! In addition to improving efficiency by reducing false reports in the final appearance inspection process, it also supports defect detection using AI. It is effective for defects with low brightness differences that are difficult to detect with inspection equipment, even though they can be identified visually.

-

【TTL】Invisible wiring with transparent FPC! Compatible with reflow mounting, ideal for display devices such as digital signage. 【Flexible Printed Circuit Board】

Transparent flexible printed circuit boards contribute to improved design with excellent transparency! Fine patterns make the wiring less noticeable. 〇 Made with polyimide that excels in heat resistance and flame retardancy. ⇒ Compatible with reflow mounting. ★ Suitable for display devices such as digital signage, as well as medical devices and transparent film antennas! ★ We also accommodate small quantities and a variety of prototypes.

Recommended products

Distributors

Taiyo TechnoRex Co., Ltd. continues to operate in the fields of prototype development of flexible printed circuit boards (FPC) and printed circuit board testing systems. Since FPC is fundamentally related to the structure of hardware, both high precision quality and shortened development time are required. We have extensive experience and know-how in the manufacturing processes of single-sided FPC, double-sided FPC, multilayer FPC, and their advanced types, and we continuously improve and enhance our technology, resulting in consistent evaluations of our delivery times and quality. Additionally, while technically advancing further miniaturization and high density, we are also undertaking new initiatives such as bump-type and special material electroplating. On the other hand, our printed circuit board testing systems mainly consist of electrical inspection systems and final appearance inspection systems, which are adopted in the mass production sites of FPCs and package/module-type substrates. They operate day and night in quality control settings for substrates used in smartphones, automotive applications, and various electronic devices. We will continue to respond to the increasingly diverse market needs. *On December 21, 2023, the company name was changed from "Taiyo Kogyo Co., Ltd." to "Taiyo TechnoRex Co., Ltd."*