腐食環境診断/対策

腐食にかかわる設備管理・品質問題を、腐食環境、耐腐食性の二つの観点から改善サポート!

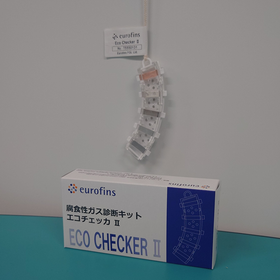

腐食にかかわる設備管理・品質問題を、腐食環境、耐腐食性の二つの観点から改善サポートいたします。 ・腐食環境診断キット(エコチェッカII、エコチェッカSUN)の使用・分析による装置や職場の腐食環境診断 ・稼働中製品の劣化状況みえる化による設備のメンテナンスの効率化 ・製品の耐腐食性評価 ・塩害調査 ・塩水噴霧試験(複合サイクル) ・ガス腐食試験 ・温湿度試験

基本情報

■腐食環境の調査 ・エコチェッカII ・エコチェッカSUN ・環境中の塩害成分調査 ■耐腐食性の評価、不具合の解析 ・特殊環境試験(ガス腐食、塩水噴霧) ・電子部品の故障解析 ・材料分析

価格帯

納期

用途/実績例

腐食環境診断と対策の実績例 ■データセンター、マシン室、コンピュータルーム ■局舎、基地局、交換機室 ■汚水処理場、浄水場 ■製紙工場、ゴム工場、化学工場、製鉄所 ■電機・電子機器の製造工場、クリーンルーム ■部品、製品の保管倉庫 ■計装設備、電力設備メンテナンス ■食品工場内貯蔵庫、冷凍室、加工場 、レストラン(銅配管) ■博物館、美術館、展示品の環境管理 ■河川、ゴミ処理場の悪臭、腐臭 (硫化水素) ■温泉地・海岸地・工場地・埋立地・交通量の多い市街地

カタログ(7)

カタログをまとめてダウンロードこの製品に関するニュース(2)

-

【無料セミナー】 電子機器、設備保全の信頼性と寿命確保の為の腐食環境ソリューション (腐食環境診断キット エコチェッカIIのご紹介)

電子機器の使用環境は様々であり、各種環境因子に起因する腐食の影響は増大する傾向にあります。 電子機器の信頼性と寿命は使用される環境に大きく依存します。 温泉、火山、ゴミ、河川などから発生した腐食性物質によって、電子部品・プリント板の配線・コネクタ接点や電機設備のスイッチ接点が腐食し、重大なトラブルがおこることがあります。 こんな課題を解決したい方へおすすめの内容です。 • 設備稼働環境の大気が要因で電子機器の故障につながる? • 温泉や汚水処理場、劣悪な環境で故障リスクを減らしたい。 • 広い工場、少ない人員・工数で環境調査を実施したい。 • 老朽化したインフラを少しでも長持ちさせたい。 弊社オリジナルの腐食環境診断キット エコチェッカII を中心とした腐食環境診断の手法をご紹介いたします。

-

【無料セミナー】電子部品の腐食トラブル ~評価と対策~

DX(デジタルトランスフォーメーション)の普及により、あらゆる分野で電子機器やデバイスが増加しています。DXが進むと共に、これらの機器が多様な環境で使用される機会が増え、腐食による品質問題が大きな課題となりつつあります。 工場やインフラ、農業、医療などの業務プロセスがデジタル化され、これに伴いIoTセンサーやエッジデバイス、ネットワーク機器などの電子機器の設置が広がります。これらの機器は必ずしも理想的な屋内環境だけでなく、厳しい環境にも配置されるため、腐食の影響が大きくなります。 本セミナーでは、腐食によるトラブルへ対する評価・解析・対策例を用いて具体的に解説を致します。 こんな品質課題をお持ちの方におすすめです! ・接続不良や短絡 ・電子機器・デバイスの劣化 ・製品寿命の短縮 ・腐食防止対策方法

おすすめ製品

取り扱い会社

ユーロフィンFQL株式会社は、株式会社富士通研究所の分析部門、富士通株式会社の品質保証部を前身とし、材料分析、信頼性評価、安全性評価、故障解析にとどまらず、サプライヤ品質管理、製造工場の監査など製品品質の向上のための活動を長きにわたり行ってきました。また、品質にかかわるヒトの育成・教育支援、品質管理・製品含有化学物質管理システム・ソフトウェア開発プロセスの構築・改善支援など、品質を担う組織の課題解決にも貢献します。 ■信頼性評価・環境試験 各種信頼性評価、二次電池・電源等の発煙・発火等の安全性検証。耐候性・ガス腐食等の特殊環境の評価 ■故障解析 電子部品・機器の故障解析や、材料に関連した特性確認、不具合の詳細解析 ■品質関連システム・プロセス構築・改善支援 QCD(Quality:品質、Cost:コスト、Delivery:納期)目標達成に向け、CMMIやAutomotive SPICEといったモデルを用い、開発プロセスの改善をご支援 ■品質関連教育 『組織を活性化したい』『品質マインドを醸成したい』『新入社員の品質教育を行いたい』などなど、課題に応じた教育プログラムをカスタマイズ