- OTHER

We will exhibit a particle visualization system at "SEMICON Japan 2025" (December 17-19, 2025 / Tokyo Big Sight, East Exhibition Hall, East Hall 6, E6729).

Shin Nippon Air Technologies Company Solution Division

We will solve the issues related to the deterioration of defect rates due to fine particles and the cleaning of manufacturing sites. The fine particle visualization system developed by Shin Nippon Air Technologies, under the ViEST brand, combines a uniquely developed ultra-sensitive camera and light source to visualize fine particles in clean rooms and equipment. It can capture their behavior in real-time while also quantifying particle information, making it a world-class visualization system. Currently, we are expanding the sale of systems and tools, as well as contract technical services utilizing them, both domestically and internationally. We have particularly rich experience in the semiconductor industry and clean rooms. The following are some examples of applications, but by using our technology, we can strongly promote solutions to various issues such as the deterioration of defect rates caused by fine foreign substances, visualization of clean airflow, and concerns regarding site cleanliness. - Visualization surveys of fine particles and airflow in manufacturing lines and environmental improvements - Promotion of cleanliness in manufacturing equipment and environments - Cleanliness evaluation of various equipment performance - Improvement of yield and quality degradation caused by contamination issues - Support for research and development requiring visualization of fine particles and airflow - Evaluation of particle generation from products.

- Date and time

- Capital

- Entry fee

Related Links

For more details, visit the "Shin Nihon Kucho ViEST" website.Related product information

-

Gas Particle Continuous Monitoring Measurement System "Particle Eye CC"

It counts particles in gas in real time while simultaneously performing particle size classification. It is a continuously monitored measurement system that can be customized according to specific purposes and applications.

- Measurement frequency: 10–120Hz - Data recording interval: 0.1–60.0 sec - Maximum resolution: 800×600 - Measurement mask: Measurement range within the image can be specified as rectangle/ellipse/trapezoid - Particle size classification: 3–5 levels (separate calibration tests are required for particle size classification) - Trigger recording mode: Video recording includes a few seconds before and after when the particle count exceeds the set threshold - Scheduled measurement mode: Automatic measurement at the set measurement time from the scheduled time - Long-term continuous monitoring: Automatic data file update at date change - Monitor display: Particle monitoring video/color classification video/time series count graph/particle size classification histogram - Signal output: Signal output when the particle count exceeds the set threshold (optional) - Signal input: Recording starts triggered by signals from external sensors (optional) - Multi-camera monitoring: Monitoring measurement with up to 4 cameras (optional) *This is a reference specification using a standard camera and a computer with dedicated software installed. *The system configuration may vary depending on the application, so specifications will be discussed as needed. For customization of specifications or details about options, please feel free to contact us through our website.

-

Airflow Visualization Device [Usable in Clean Rooms, Free Demo Unit Available]

Airflow Visualization Device [Usable in Clean Rooms, Free Demo Unit Available]In clean rooms and general rooms, airflow can be easily visualized and evaluated with good visibility through simple operation.

The product pages for each item are as follows: Compact Rechargeable Pure Water Mist Generator "plus TRACER" https://www.ipros.jp/product/detail/2000179897 D Light Type-F, Type-P https://www.ipros.jp/product/detail/2000218091 For more details, please refer to the catalogs available on each page. Feel free to contact us with any inquiries.

-

A highly experienced microparticle visualization system for solving foreign matter contamination issues.

A highly experienced microparticle visualization system for solving foreign matter contamination issues.Are you struggling with the contamination or adhesion of tiny foreign particles? Our experienced particle and airflow visualization system can help improve your yield. Please feel free to consult with us!

Particle Visualization Dedicated Camera Specifications ■STD Body Dimensions: W58 × D160 × H42 [mm] Maximum Resolution: 1920 × 1080 Frame Rate: Up to 60Hz (depending on resolution, etc.) Detectable Particle Size*: 0.2μm ■HS Body Dimensions: W87 × D102 × H74 [mm] Maximum Resolution: 1600 × 1100 Frame Rate: Up to 1600Hz (depending on resolution, etc.) Detectable Particle Size*: 0.2μm ■EX Body Dimensions: W103 × D152 × H105 [mm] Maximum Resolution: 1920 × 1920 Frame Rate: Up to 120Hz (depending on resolution, etc.) Detectable Particle Size*: 0.09μm *The detectable particle size is a reference value based on our proprietary standards. It may vary depending on the visualization target and usage environment. ★A light source is also necessary for visualization. Information about light sources is available on our website. ⇒ Laser light sources suitable for high-sensitivity imaging. LED light sources capable of visualizing particles that were previously difficult to detect. ★If you have any questions, please feel free to contact us. Our specialized visualization technical staff will assist you.

-

Three products for visualizing airflow and surface foreign objects.

Three products for visualizing airflow and surface foreign objects.[Demo unit available for loan] Suitable as a daily use tool for quality control.

The product listing pages are as follows: Compact Rechargeable Pure Water Mist Generator "plus TRACER" https://www.snk.co.jp/viest/product/product6.html D-Light Type-F, Type-P https://www.snk.co.jp/viest/product/product5.html For more details, please refer to the catalog. Feel free to contact us.

-

[Environmental Pollution Problem Solving] Suspended Particles and Adhering Particles Visualization Evaluation System

[Environmental Pollution Problem Solving] Suspended Particles and Adhering Particles Visualization Evaluation SystemAre you troubled by the contamination or adhesion of foreign substances? Our experienced particle and airflow visualization system will solve your quality issues. Please feel free to consult with us!

■Particle Eye STD Dimensions: W58 × D160 × H42 [mm] (excluding lens) Maximum Resolution: 1920 × 1080 Frame Rate: Up to 60Hz (depending on resolution) Detectable Particle Size*: 0.2μm ■Particle Eye HS Dimensions: W87 × D102 × H74 [mm] (excluding lens) Maximum Resolution: 1600 × 1100 Frame Rate: Up to 2500Hz (depending on resolution) Detectable Particle Size*: 0.2μm ■Particle Eye EX Dimensions: W103 × D152 × H105 [mm] (excluding lens) Maximum Resolution: 1920 × 1920 Frame Rate: Up to 120Hz (depending on resolution) Detectable Particle Size*: 0.09μm *The detectable particle size is a reference value based on our proprietary standards. It may vary depending on the visualization target and usage environment. *Lighting is also required for visualization. Information about lighting is available on our website. ⇒https://www.snk.co.jp/viest/technology.html *If you have any questions, please feel free to contact us at any time. Our specialized technicians will assist you.

-

High-definition purity clean room rental [Short-term and long-term use available!]

Easily utilize an ultra-clean environment. Ready to use, suitable for short-term and long-term projects. Class 1 clean room available for rental.

ISO Class 1 Total area: 22m² × 2.7m CH Available hours: Weekdays 9:00 AM - 5:30 PM Floor fully grating (load capacity 300kg/m²) Ceiling fully FFU (start/stop free, variable wind speed 0, 0.10–0.30m/s) Air conditioning control and variable temperature and humidity (temperature 20–28℃ DB, humidity variable 30–70% RH) Dedicated operator available, 200V power supply available (additional construction required), pure water supply available (18.2MΩ・cm or less) Internet (wireless LAN) fully equipped Room available (may need to share with company staff depending on the situation of the day) Other facilities negotiable. Address: 7033-182 Miyagawa, Chino City, Nagano Prefecture, 391-0013 Japan

-

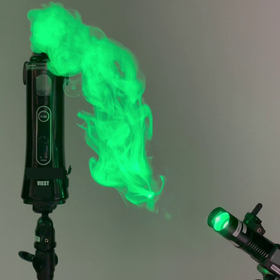

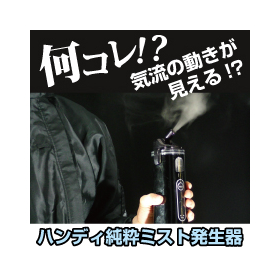

Handheld Pure Water Mist Generator "plus TRACER"

Handheld Pure Water Mist Generator "plus TRACER"★Free demo unit and introduction video available★ Handheld mist generator that makes the flow of air visible with pure water fine mist.

【Usage Examples】 ○ Observation of airflow in the room ○ Confirmation of pressure difference between rooms ○ Verification of the performance of various exhaust systems ○ Validation of airflow analysis results ○ Confirmation of airflow in safety cabinets ○ Verification during the introduction of new equipment and systems ● For more details, please download the catalog or contact us.

-

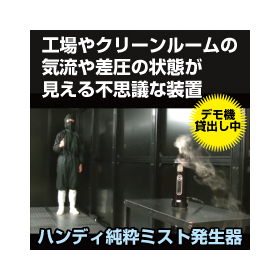

Handheld pure water mist generator & visualization light for surface foreign object identification

★Free rental demo units available★ Visualize airflow with fine mist! An ultra-lightweight mist generator weighing about 500g and a light that makes falling dust and adhering particles visible.

○ Handy Pure Water Mist Generator 'plusTRACER Model01' This product uses pure water (distilled water) to create ultra-fine mist, visualizing the "airflow" and "differential pressure" conditions within factories and clean rooms. It visualizes airflow movements with fine mist! Weighing approximately 500g, it is ultra-lightweight and cordless, making it effective in hard-to-reach places such as high locations, narrow spaces, and inside equipment cases. Features: Mist is extremely fine, measuring several micrometers, making it suitable for use around precision equipment. Generates room-temperature mist. Can be operated remotely from a distance. Can be mounted on a tripod for fixed installation. ○ Surface Foreign Object Identification Visualization Tool "D Light" Allows visual detection and identification of falling dust and adhered particles! Ideal for quality control in factories and daily hygiene management in hospitals and welfare facilities. Using ultraviolet LED as the light source, this new visualization tool detects falling dust and adhered particles, and by observing the differences in fluorescent colors emitted by the particles, it can identify the types of particles. It is part of the "ViEST" (registered trademark) lineup, a brand specializing in particle visualization.

-

Particle Visualization System "Parallel Eye H" [Environmental Survey / Performance Evaluation]

Particle Visualization System "Parallel Eye H" [Environmental Survey / Performance Evaluation][Web Demo in Progress] Achieve highly sensitive visualization of particles and airflow with our unique visualization system!

Ultra-high sensitivity camera for particle visualization "Particle Eye" Ultra-high sensitivity laser sheet light source for particle visualization "Parallel Eye H" Technical information featuring evaluation examples of particle visualization The URLs will take you to the product pages on our dedicated visualization website. Options and more We offer a variety of custom solutions that combine hardware such as light source units and cameras with software for counting, as well as various tracer generation devices for visualizing airflow, tailored to your specific applications.

-

Simulation Evaluation Service

Simulation Evaluation ServiceImprovement of overall airflow in the cleanroom, temperature distribution in the manufacturing area, airflow planning.

-

-

Particle Visualization System "Parallel Eye M"

Particle Visualization System "Parallel Eye M"[Demo units available] Floating particles in the space and adhering particles on the surface can be seen with the naked eye!

【For those with such challenges】 - Visualization evaluation of floating foreign substances - Visualization evaluation of surface foreign substances - Identification of yield loss causes due to particles and airflow - Feeling that we are not getting closer to the causes of foreign substance contamination - Concerned whether planned local cleaning and dust collection equipment will be worth the investment - Tried various methods but have given up thinking it’s invisible - Struggling with being introduced to visualization technologies that lack sufficient sensitivity - Studying cleanroom practices but questioning their applicability to my own site - Yield improvement is not achieved with just particle counters and general analysis - Not concerned about fine particles, but rather want to evaluate coarse particles and dust - Want to manage the manufacturing environment on a daily basis - Evaluation of cleaning equipment such as vacuum cleaners

-

Ultra-high sensitivity particle visualization dedicated camera "Particle Eye" series

Ultra-high sensitivity particle visualization dedicated camera "Particle Eye" series[Web demo in progress] A visualization-specific ultra-high-sensitivity camera equipped with the unique image processing technology "ViEST Engine," capable of visualizing the behavior of fine particles and airflow!

■ Standard model "Particle Eye STD" Dimensions: W58 × D160 × H42 [mm] (excluding lens) Maximum resolution: 1920 × 1080 Frame rate: Up to 60Hz (dependent on resolution) Reference sensitivity*: 0.2μm ■ High-speed shooting compatible model "Particle Eye HS" Dimensions: W87 × D102 × H74 [mm] (excluding lens) Maximum resolution: 1600 × 1100 Frame rate: Up to 2,500Hz (dependent on resolution) Reference sensitivity*: 0.2μm ■ Ultra-high sensitivity model "Particle Eye EX" pursuing low light sensitivity Dimensions: W103 × D152 × H105 [mm] (excluding lens) Maximum resolution: 1920 × 1920 Frame rate: Up to 120Hz (dependent on resolution) Reference sensitivity*: 0.09μm For details, please download the materials and check. *Reference sensitivity based on our unique combination with the laser light source "Parallel Eye H" when using the standard lens.

-

Handheld Pure Water Mist Generator "plusTRACER Model01"

Handheld Pure Water Mist Generator "plusTRACER Model01"★Free demo unit and introduction video available★ Handheld mist generator that makes the flow of air visible with pure water fine mist.

【Usage Examples】 ○ Observation of airflow in the room ○ Confirmation of pressure differences between rooms ○ Verification of the performance of various exhaust systems ○ Validation of airflow analysis results ○ Confirmation of airflow in safety cabinets ○ Verification during the introduction of new equipment and systems ● For more details, please download the catalog or contact us.

-

Particle Visualization System: Comprehensive Evaluation Service for Generated Particles

Particle Visualization System: Comprehensive Evaluation Service for Generated ParticlesEvaluation of dust generation from mechanical parts and various materials. Real-time counting of the total amount of generated fine particles and particle size classification. Includes an evaluation report.

~Fine Particle Generation Measurement Device P-Wind~ For more details, click here: https://www.snk.co.jp/viest/technology.html For inquiries, click here: https://www.snk.co.jp/info/form.html?frmid=33 Please be sure to download and view the catalog as well.

-

Particle Visualization" Ultra High Sensitivity System Dedicated Camera "Particle Eye

Particle Visualization" Ultra High Sensitivity System Dedicated Camera "Particle EyeAre you troubled by oil mist, fumes, and foreign substances generated during processing? This is a fine particle visualization system that has solved many problems that are not visible to the naked eye.

■Particle Eye STD Dimensions: W58 × D160 × H42 [mm] (excluding lens) Maximum Resolution: 1920 × 1080 Frame Rate: Up to 60Hz (dependent on resolution) Detectable Particle Size*: 0.2μm (200nm) ■Particle Eye HS Dimensions: W87 × D102 × H74 [mm] (excluding lens) Maximum Resolution: 1600 × 1100 Frame Rate: Up to 2,500Hz (dependent on resolution) Detectable Particle Size*: 0.2μm (200nm) ■Particle Eye EX Dimensions: W103 × D152 × H105 [mm] (excluding lens) Maximum Resolution: 1920 × 1920 Frame Rate: Up to 120Hz (dependent on resolution) Detectable Particle Size*: 0.09μm (90nm) *The detectable particle size is a reference value based on our proprietary standards. It may vary depending on the visualization target and usage environment, so please feel free to consult our specialists for detailed information.

-

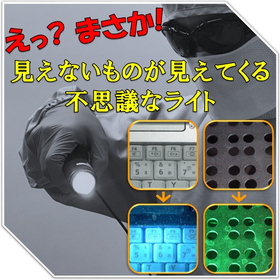

Surface observation tool "D-Light" for detecting foreign substances, dirt, and scratches.

Surface observation tool "D-Light" for detecting foreign substances, dirt, and scratches.[Demo unit available for loan] It can visualize foreign substances, dirt, and scratches on the surface. It is well-received as a daily use tool for yield management, quality control, cleaning management, and hygiene management!

■Weight: 181 [g] ■Dimensions: W139 × D22 × H33 [mm] ■Light Color: ・D-Light Type-F: Violet ・D-Light Type-P: Green

-

Surface Foreign Object High Sensitivity Identification Visualization System "D-Scope"

It excels in high sensitivity detection, quantification, and portability, making it suitable for quality inspection and research and development settings. It contributes to the detection of minute foreign substances and scratches, as well as their quantitative evaluation.

■Image Analysis■ - Images captured on-site can be analyzed using dedicated post-processing software to identify the specific colors and shapes of foreign objects and contaminants. Particle counting. Acquisition of shape information. Acquisition of color information. Various image processing functions. Histogram display of particle information. Filtered display. Partial magnification display. Distance measurement. For detailed information obtained from the analysis, please feel free to contact our representative. ■High-Resolution Imaging■ - With a standard camera lens, it is possible to detect foreign objects larger than approximately 20μm and digitize shape information. Additionally, using optional camera lenses, evaluation of foreign objects on the micron order is possible.

-

Surface observation tool "D-Light" for detecting foreign objects, dirt, and scratches.

Surface observation tool "D-Light" for detecting foreign objects, dirt, and scratches.Visualize surface foreign substances, dirt, and scratches! It is well-received as a daily management tool for yield management, quality control, cleaning management, and hygiene management. *Demo units available for loan.

■Weight: 181 [g] ■Dimensions: W139 × D22 × H33 [mm] ■Light Color: D-Light Type-F: Violet D-Light Type-P: Green ■Usage Scenarios: Stationary: Can be installed inside equipment or on a desk for long continuous illumination Portable: Can be used without a power cord (up to 4 hours; please consult us if longer usage is needed) ■Applications: By combining with our product 'D-Scope', it enables photography, recording, and particle analysis.

-

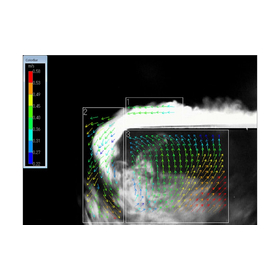

Flow velocity vector measurement software "plus PIV"

Flow velocity vector measurement software "plus PIV"[Web demo in progress] Measurement procedure is a simple 4-step process that allows for PIV (velocity distribution measurement).

■Measurement Method: PIV (Particle Image Velocimetry) ■Measurement Results: Average velocity, standard deviation, minimum/maximum (velocity, X velocity, Y velocity) ■Input Files: AVI, WMV ■Output Files: Measurement results file (CSV), result image file (BMP) ★Even those who do not know image processing can easily output airflow velocity distribution using airflow visualization videos from that day "plus PIV" https://www.snk.co.jp/viest/product/product7.html ★Contact form can be found here https://www.snk.co.jp/info/form.html?frmid=33

-

[★Demo unit available for loan] Airflow visualization set

[★Demo unit available for loan] Airflow visualization setEasily visualize airflow with good visibility.

The listing pages for each product are as follows: Compact Rechargeable Pure Water Mist Generator "plus TRACER" https://www.ipros.jp/product/detail/2000179897 D-Light Type-F, Type-P https://www.ipros.jp/product/detail/2000218091 For more details, please refer to the catalog on each page. Feel free to contact us.

-

Foreign Object Detection: Environmental Survey, Product Evaluation, Performance Testing Services

Foreign Object Detection: Environmental Survey, Product Evaluation, Performance Testing ServicesDo you want to check if dust collection is effective? Are you struggling with compliance to specialized regulations? Our fine particle visualization technology can solve this!

We can solve the following concerns. If any of these resonate with you, please feel free to contact us. □ Decreased yield due to particles and airflow □ Training for cleanroom operators □ Questions about the cleanroom environment □ Quality defects due to foreign substances in painting and coating processes □ Quality and appearance defects due to foreign substances (contamination) and scratches in the assembly process □ Foreign substance contamination in the drug encapsulation process □ Questions about the air environment in the operating room □ Want to express the product strength of our own products through video □ Particle contamination due to static electricity □ Want to see airborne dust in our own environment without any reasoning □ Want to observe foreign substances and scratches adhered to surfaces □ Want to design airflow for equipment □ Need visual materials for internal deployment of improvement activities □ Want to visualize welding fumes and other substances to comply with specific regulations *Please share your concerns with us (URL: Our inquiry site) https://www.snk.co.jp/particle/inquiry.html *We have simple case videos introduced on our website. https://www.snk.co.jp/particle/example1.html

-

【Towards Solving Foreign Matter Issues】Suspended Particles and Adhering Particles Visualization Evaluation System

【Towards Solving Foreign Matter Issues】Suspended Particles and Adhering Particles Visualization Evaluation SystemAre you troubled by the contamination or adhesion of fine foreign substances? Our experienced particle and airflow visualization system contributes to improving defect rates. Please feel free to consult with us!

Particle Visualization Dedicated Camera Specifications ■STD Body dimensions: W58 × D160 × H42 [mm] Maximum resolution: 1920 × 1080 Frame rate: Up to 60Hz (depending on resolution, etc.) Detectable particle size*: 0.2μm ■HS Body dimensions: W87 × D102 × H74 [mm] Maximum resolution: 1600 × 1100 Frame rate: Up to 1600Hz (depending on resolution, etc.) Detectable particle size*: 0.2μm ■EX Body dimensions: W103 × D152 × H105 [mm] Maximum resolution: 1920 × 1920 Frame rate: Up to 120Hz (depending on resolution, etc.) Detectable particle size*: 0.09μm *The detectable particle size is a reference value based on our proprietary standards. It may vary depending on the visualization target and usage environment. ★A light source is also necessary for visualization. Information regarding light sources is also available on our website. ⇒https://www.snk.co.jp/particle/ ★If you have any questions, please feel free to contact us at any time. Our specialized technicians will assist you.

-

[Foreign Matter Management] Suspended Particles and Adhering Particles Visualization Evaluation System

[Foreign Matter Management] Suspended Particles and Adhering Particles Visualization Evaluation SystemAre you troubled by the contamination or adhesion of fine foreign substances? Our experienced particle and airflow visualization system contributes to improving defect rates. Please feel free to consult with us!

Particle Visualization Dedicated Camera Specifications ■STD Body Dimensions: W58 × D160 × H42 [mm] Maximum Resolution: 1920 × 1080 Frame Rate: Up to 60Hz (depending on resolution, etc.) Detectable Particle Size*: 0.2μm ■HS Body Dimensions: W87 × D102 × H74 [mm] Maximum Resolution: 1600 × 1100 Frame Rate: Up to 1600Hz (depending on resolution, etc.) Detectable Particle Size*: 0.2μm ■EX Body Dimensions: W103 × D152 × H105 [mm] Maximum Resolution: 1920 × 1920 Frame Rate: Up to 120Hz (depending on resolution, etc.) Detectable Particle Size*: 0.09μm *The detectable particle size is a reference value based on our proprietary standards. It may vary depending on the visualization target and usage environment. ★A light source is also necessary for visualization. Information regarding light sources is available on our website. ⇒https://www.snk.co.jp/viest/ ★If you have any questions, please feel free to contact us at any time. Our specialized technicians will assist you.

-

Airflow visualization system "Handheld dry mist generator"

Airflow visualization system "Handheld dry mist generator"[Demo unit available for loan] A handheld mist generator that allows airflow checks with pure water fine mist. Since it uses pure water mist, it can also be used in clean rooms!

【Usage Examples】 ○ Observation of airflow within a room ○ Checking differential pressure between rooms ○ Performance verification of various exhaust systems ○ Validation of airflow simulation results ○ Evaluation of containment performance of safety cabinets ○ Verification during the introduction of various equipment and systems ● For more details, please download the PDF or contact us.

-

High-capacity spray type pure water mist generator "plus FOG"

[Web Demo in Progress] The mist spray volume can be adjusted in multiple stages. Ideal for wide-area and multi-point airflow visualization!

■Weight: Approximately 12 [kg] ■Dimensions: W370 × D330 × H370 [mm] (main unit only) ■Mist generation method: Ultrasonic method ■Spray volume: Approximately 1L/h ■Accessories: AC adapter, instruction manual, hose, pipe with small holes, sockets, water supply bottle, funnel

-

Three new products for fluid and particle control to achieve a clean space.

Three new products for fluid and particle control to achieve a clean space.Comprehensive catalog giveaway! The latest particle measurement equipment to assist with cleaning.

【Product Features】 ■ Mobile Visualization System "TYPE-S" - Detection of filter leaks and more - Integrated light source and camera - Compact and lightweight - New type of optical film monitoring method - Visualization of fine particle behavior - Real-time counting of particles 0.5μm and larger ■ Handheld Pure Water Mist Generator "plusTRACER" - Lightweight handheld type weighing approximately 500g - Remote operation available - Observation of airflow within a room - Confirmation of pressure differences between rooms - Performance verification of various exhaust systems - Validation of airflow analysis results - Airflow confirmation in safety cabinets - Verification during the introduction of new equipment and systems ■ Flow Velocity Distribution Measurement Software "plus PIV" - Measurement method: Reading image files - Setting measurement scene range and starting measurement - Setting measurement area, parameters, scale time, and arrow shape color bar - Display of measurement results *For more details, please download the catalog or contact us.

-

Microparticle Visualization System

Microparticle Visualization System[Web Demo in Progress] See the causes of yield deterioration! We visualize and analyze microparticles and airflow from the clean room to the inside of manufacturing equipment!

[For those with such issues] - I feel like I'm not getting any closer to identifying the cause of contamination. - I'm worried whether the planned local purification and dust collection equipment will be worth the investment. - I've tried various things but have given up thinking it's invisible. - I want to visualize and verify the containment effect. - I'm struggling with being introduced to visualization technologies that have insufficient sensitivity. - The airflow visualization device lacks sensitivity, and I'm having trouble with tracer selection and other issues. - I want to evaluate surface foreign matter that has adhered to the product as a result, rather than just airborne particles. - I'm studying clean-up processes but I'm unsure if they apply to my own site. - Just using particle counters and general analysis isn't improving yield. - I'm not concerned about fine particles; rather, I want to evaluate coarse particles and dust. - The contamination occurring within the production equipment is not being resolved easily. - I want to visualize airflow in large spaces and server rooms. - I want to optimize the layout of clean rooms and production equipment. - I would like to use visualization in the validation of pharmaceutical processes. - I'm looking for a contractor for airflow simulation at a site without CAD drawings. - I want to visualize welding fumes and other substances to comply with specialized regulations.

Related catalog

Mobile Visualization Counting Device "Type-S"

Ultra-high sensitivity particle visualization dedicated camera "Particle Eye" series