[GDMS] Glow Discharge Mass Spectrometry

Dissociate and fragment specific mass ions, and detect them with a mass spectrometer.

GDMS is a method for analyzing the composition of solid samples, allowing simultaneous analysis from major components to trace elements, and performing semi-quantitative analysis of impurities present in the sample. The concentration conversion uses the relative sensitivity factor (RSF) associated with the device. The analytical values are derived from the ion intensities of the major component elements and the target elements, calculated using the RSF, resulting in semi-quantitative values. - Bulk analysis is possible from trace elements (ppb level) to major component levels. - Depth profile analysis on the order of micrometers and thin film analysis are possible. - By using conductive materials and auxiliary electrodes, analysis of semiconductor materials and insulating materials is also possible. - High mass resolution allows for the removal of interfering ions. - Measurement is possible for almost all elements below Li, excluding hydrogen and noble gases. - Isotope ratio measurement is possible.

basic information

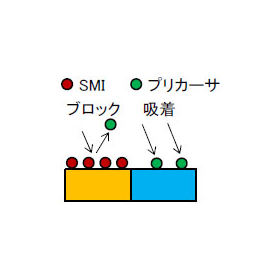

Under an Ar atmosphere, the sample is used as the negative electrode for glow discharge. The Ar gas collides with the sample, causing the constituent elements of the sample to be sputtered. Most of the elements released by sputtering are neutral but become ionized in the Ar plasma. The ionized atoms are measured using a double-focusing mass spectrometer to determine the qualitative and quantitative analysis of the elements. Depending on the sample content and analysis purpose, the processing method for the sample is selected. Pin cell method: Suitable when the sample is easy to process. It is suitable for bulk analysis. Flat cell method: Suitable when the surface of the sample is flat. It is suitable for film analysis and depth profiling.

Price information

-

Delivery Time

Applications/Examples of results

- Analysis of impurities in semiconductor materials - Analysis of high-purity metals - Analysis of impurities in alloys - Analysis of impurities in plating films - Analysis of impurities in powders

Detailed information

-

Please consult with us first. ★ We will start with a proposal for the analysis plan ★ We can also meet at your company, of course. We will carefully explain the analysis results and leave no questions unanswered. Please contact us at 03-3749-2525 or info@mst.or.jp!

-

We will conduct a visiting seminar. ★ We offer free seminars tailored to the needs of our customers, featuring visits from our engineers. ★ We will introduce analysis techniques and explain analysis data according to your requests. ◆ Example seminar content - A broad explanation of MST analysis methods - A detailed explanation of specific analysis methods from the principles - Explanation of the analysis data requested by the customer Please contact us at 03-3749-2525 or info@mst.or.jp!

Recommended products

Distributors

MST is a foundation that provides contract analysis services. We possess various analytical instruments such as TEM, SIMS, and XRD to meet your analysis needs. Our knowledgeable sales representatives will propose appropriate analysis plans. We are also available for consultations at your company, of course. We have obtained ISO 9001 and ISO 27001 certifications. Please feel free to consult us for product development, identifying causes of defects, and patent investigations! MST will guide you to solutions for your "troubles"!