Lock-in thermal analysis method

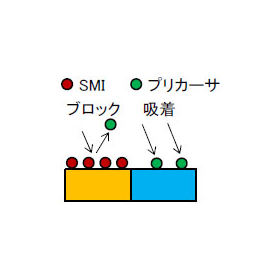

The lock-in thermal analysis method detects slight temperature increases in the current path.

- The IR-OBIRCH function is also included, allowing for further narrowing down of the fault location after identifying the heat generation area through IR-OBIRCH measurement. - By detecting infrared, it is possible to non-destructively identify fault locations without the need for opening the package through etching or removing electrodes. - By using lock-in signals, it is possible to identify heat generation areas with high S/N, enabling cross-sectional analysis such as Slice & View.

basic information

It is a semiconductor failure analysis device that detects heat generated inside the device and identifies the failure location. By overlaying the heat generation images detected by a high-sensitivity infrared detector with high-resolution pattern images obtained from an IR confocal laser microscope, it quickly identifies the failure location with high sensitivity and high positional accuracy.

Price information

-

Delivery Time

Applications/Examples of results

■Symptoms - Wiring leakage or short circuit defects - Identification of electrostatic destruction points - Measurement of heat distribution on the light-emitting element - Microplasma leakage and insulation defects in the oxide film - Measurement of heat distribution on the light-emitting element ■Devices - Si devices (transistors, MOSFETs, IGBTs, CMOS sensors) - SiC power devices (Schottky barrier diodes, MOSFETs, etc.) - GaN light-emitting elements and GaN devices (LD, LED, HEMT, etc.) - MEMS (pressure sensors, accelerometers) - Identification of insulation degradation areas in ICs, substrates, etc.

Detailed information

-

Please consult with us first. ★ We will start by proposing an analysis plan ★ Meetings at your company are, of course, possible. We will carefully explain the analysis results and leave no questions unanswered. Please contact us at 03-3749-2525 or info@mst.or.jp!

-

We will hold a visiting seminar. ★ We offer free seminars tailored to the needs of our customers, featuring visits from our engineers. ★ Depending on your requests, we will introduce analysis techniques and explain analysis data. ◆ Examples of seminar content - A broad explanation of MST analysis methods - A detailed explanation of specific analysis methods from the principles - An explanation of the analysis data requested by the customer Please contact us at 03-3749-2525 or info@mst.or.jp!

Recommended products

Distributors

MST is a foundation that provides contract analysis services. We possess various analytical instruments such as TEM, SIMS, and XRD to meet your analysis needs. Our knowledgeable sales representatives will propose appropriate analysis plans. We are also available for consultations at your company, of course. We have obtained ISO 9001 and ISO 27001 certifications. Please feel free to consult us for product development, identifying causes of defects, and patent investigations! MST will guide you to solutions for your "troubles"!