[Analysis Case] Fluorescent X-ray Analysis Case of Metal Materials

As a metal composition evaluation, we recommend starting with elemental screening using XRF analysis.

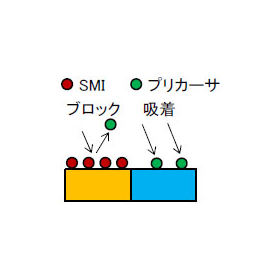

When conducting elemental analysis, it is possible to establish an efficient evaluation plan by first using XRF analysis to non-destructively examine the elements contained in the target before moving on to detailed analysis. In this case, we present data from XRF analysis conducted on blades for metal cutting. By performing surface analysis over a wide range on the order of millimeters, we roughly examined the distribution of metallic elements in the material and estimated the metal composition by calculating the elemental composition from the XRF point analysis results of characteristic areas. Measurement method: XRF Product field: Manufacturing equipment, parts, daily necessities Analysis purpose: Composition evaluation, identification, composition distribution evaluation, failure analysis, defect analysis For more details, please download the materials or contact us.

basic information

For more details, please download the materials or contact us.

Price information

-

Delivery Time

Applications/Examples of results

Analysis of manufacturing equipment, parts, and daily necessities.

catalog(1)

Download All CatalogsRecommended products

Distributors

MST is a foundation that provides contract analysis services. We possess various analytical instruments such as TEM, SIMS, and XRD to meet your analysis needs. Our knowledgeable sales representatives will propose appropriate analysis plans. We are also available for consultations at your company, of course. We have obtained ISO 9001 and ISO 27001 certifications. Please feel free to consult us for product development, identifying causes of defects, and patent investigations! MST will guide you to solutions for your "troubles"!