イオンポリッシュ法を用いた断面加工

試料表面から試料原子が弾き飛ばされるスパッタリング現象 を利用して、試料表面を削り取る方法

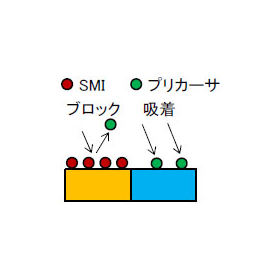

IP法は、エネルギーおよび方向を揃えたイオンビームを試料に照射したときに試料表面から試料原子が弾き飛ばされるスパッタリング現象を利用して、試料表面を削り取る方法です。 CP法(Cross-section Polish)とも言われます。 イオン種は通常試料との化学反応の心配のない希ガス(MSTではAr)が用いられます。加工面のAES分析では遮光板成分(Ni、P)は検出下限以下でした。 ■特徴 ・広域(約500μm~1mm)断面加工が可能 ・機械研磨ダメージの影響がない ・表面汚染がほとんどない ・大気非暴露、冷却加工が可能

基本情報

詳しくは、お問い合わせください。

価格帯

納期

用途/実績例

? 硬さの異なる積層膜の断面観察 ? 界面で剥離が起こる膜の断面観察 ? 結晶粒(EBSD)観察 ? FIB加工(TEM観察用)・AES分析

カタログ(1)

カタログをまとめてダウンロードおすすめ製品

取り扱い会社

MSTは受託分析サービスをご提供する財団法人です。 TEM・SIMS・XRDなど、さまざまな分析装置を保有し、分析ニーズに応えます。 知識豊富な営業担当が、適切な分析プランをご提案。貴社に伺ってのご相談も、もちろん可能です。 ISO9001・ISO27001取得。 製品開発・不良原因の解明・特許調査はぜひご相談ください! MSTは、あなたの「困った!」を解決へと導きます。