[FIB] Focused Ion Beam Processing

FIB refers to a focused ion beam with a diameter ranging from a few nanometers to several hundred nanometers, which can be used to scan the sample surface to etch or deposit material in specific areas.

FIB refers to a focused ion beam with diameters ranging from several nanometers to several hundred nanometers, which can be used to etch specific areas (sputtering) or deposit materials such as carbon (C), tungsten (W), and platinum (Pt) onto specific regions by scanning the sample surface. Additionally, the shape of the processed sample can be recognized through SIM images, which detect secondary electrons generated by irradiating the sample with the ion beam. - Arbitrary shape processing through etching in micro-regions (several nanometers to several tens of micrometers) is possible (typical processing size: around 20 μm) - Sample preparation for SEM, SEM-STEM, and TEM imaging (cross-sections of specific areas can be produced) - Fine pattern deposition and thin film formation (C, W, Pt deposition) are possible in the range of several micrometers to several tens of micrometers - High-resolution SIM (Scanning Ion Microscope) imaging is possible (acceleration voltage 30 kV: 4 nm) - Observation of metal crystal grains (Al, Cu, etc.) is possible with SIM images.

basic information

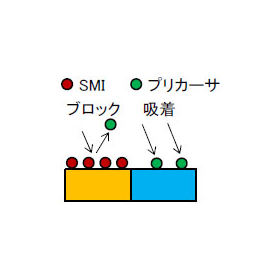

■Sample processing using fine ion beams When Ga ions are irradiated onto the sample surface, atoms and molecules that make up the sample surface are ejected into the vacuum along with the Ga. By applying this sputtering phenomenon to etching, smooth cross-sections can be produced with sub-micron precision, or holes can be drilled. ■Formation of three-dimensional structures using raw gas supply By spraying raw gas onto the sample surface to adsorb it and then irradiating a focused ion beam onto the desired area, only the irradiated portion undergoes a chemical change, resulting in the formation of a deposition thin film in that area. ■Observation using a secondary electron detector The sample surface is scanned with a focused ion beam narrowed down to the sub-micron order, and the secondary electrons emitted from the surface during this process are detected and captured as an image on a display. This is referred to as a scanning ion microscope image (SIM image).

Price information

-

Delivery Time

Applications/Examples of results

- Sample preparation for SEM, SEM-STEM, and TEM imaging (cross-sectioning of specific areas is possible) - Wiring processing (short circuits and disconnections) - Slice & View measurement of SEM and SIM images - Location identification using linkage with coordinates - SIM image observation

Detailed information

-

Please consult with us first. ★ We will start by proposing an analysis plan ★ Meetings at your company are, of course, possible. We will carefully explain the analysis results and leave no questions unanswered. Please contact us at 03-3749-2525 or info@mst.or.jp!

-

We will hold a visiting seminar. ★ We offer free seminars with engineers tailored to our customers' needs ★ We will introduce analytical techniques and explain analytical data according to your requests. ◆ Example seminar content - A broad explanation of MST's analytical methods - A detailed explanation of specific analytical methods from the principles - An explanation of the analytical data requested by the customer Please contact us at 03-3749-2525 or info@mst.or.jp!

News about this product(1)

Recommended products

Distributors

MST is a foundation that provides contract analysis services. We possess various analytical instruments such as TEM, SIMS, and XRD to meet your analysis needs. Our knowledgeable sales representatives will propose appropriate analysis plans. We are also available for consultations at your company, of course. We have obtained ISO 9001 and ISO 27001 certifications. Please feel free to consult us for product development, identifying causes of defects, and patent investigations! MST will guide you to solutions for your "troubles"!